TPE injection molding meets parts’ flexibility, durability, and efficient production by combining the elasticity of rubber with the processability of plastics. This approach enables high-volume output of soft-touch components, seals, and grips.

What is TPE?

Thermoplastic elastomers (TPEs) are a class of polymers that combine the elastic properties of rubber with the processability of thermoplastics. Unlike conventional thermoset rubber, which requires vulcanization, TPEs can be melted, injected, and cooled multiple times without significant degradation, making them ideal for efficient mass production.

Advantages of TPE Materials

- High elasticity with elongation exceeding 300% and full recovery.

- Good abrasion resistance for repeated contact.

- Low compression set, maintaining shape under load.

- Resistance to oils, greases, and weak acids.

- Operating temperature range from –30°C to +150°C.

- Electrical insulation with dielectric strength above 20 kV/mm.

Disadvantages of TPE Materials

- Softening above 150°C restricts high-heat environments.

- Poor resistance to strong solvents and concentrated acids.

- Higher shrinkage (1–5%) compared to rigid plastics.

- Potential UV degradation without stabilizers.

- Lower tear strength than silicone in extreme conditions.

- Cost higher than commodity plastics like PE.

Types of Thermoplastic Elastomers

Thermoplastic elastomers are categorized into several types, each with unique properties and applications:

TPU (Thermoplastic Polyurethane): Known for high abrasion resistance, good elasticity, and chemical resistance. Common in footwear soles, medical tubing, and industrial components.

TPV (Thermoplastic Vulcanizates): Combines rubber-like properties with thermoplastic processability. Used in automotive seals, gaskets, and vibration-damping parts.

TPO (Thermoplastic Olefin): Lightweight, UV-resistant, and chemically stable. Often used in automotive panels and roofing membranes.

SEBS (Styrene-Ethylene-Butylene-Styrene): Offers excellent flexibility and weather resistance. Suitable for soft-touch grips and overmolding applications.

Other Blends: Specialized TPE grades may incorporate fillers or additives to achieve tailored hardness, color, or friction properties.

TPE Properties

The properties of thermoplastic elastomers vary depending on the type and formulation. The table below summarizes typical performance metrics for common TPE types:

| Property | TPU | TPV | TPO | SEBS |

|---|---|---|---|---|

| Hardness (Shore A) | 70–95 | 60–80 | 50–70 | 30–70 |

| Tensile Strength (MPa) | 25–60 | 15–40 | 10–25 | 8–20 |

| Elongation at Break (%) | 400–700 | 300–500 | 200–400 | 300–600 |

| Temperature Range (°C) | -40 to 120 | -40 to 130 | -30 to 110 | -50 to 120 |

| Chemical Resistance | Excellent | Good | Moderate | Good |

| UV Resistance | Moderate | Good | Excellent | Excellent |

How to Use Thermoplastic Elastomers in Injection Molding?

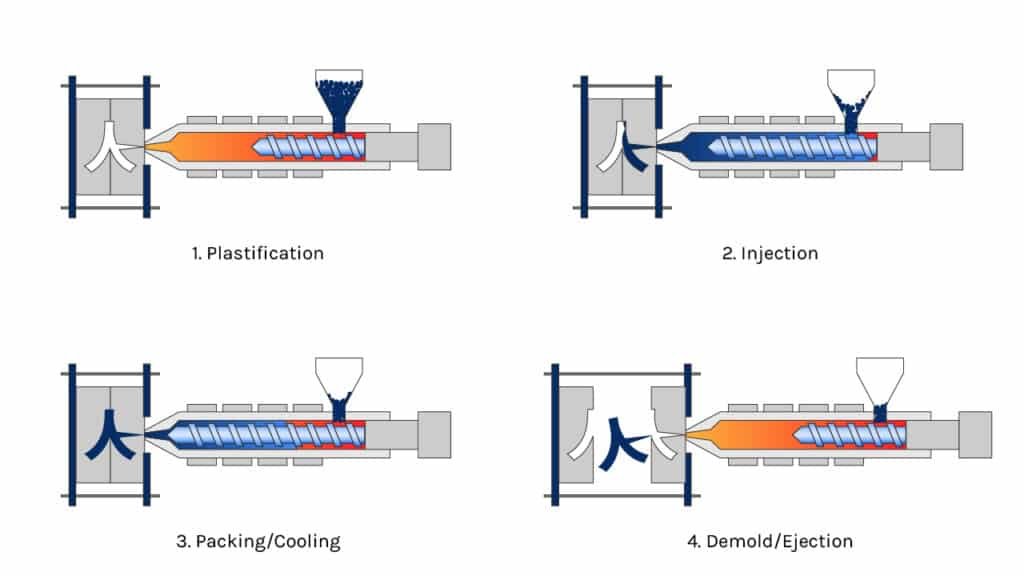

TPE molding service follows standard steps with material-specific controls.

- Material Preparation: TPE granules are dried and pre-heated to remove moisture.

- Melting: Granules are fed into a heated barrel where they are melted to a uniform consistency.

- Injection: The molten TPE is injected into a mold under controlled pressure and temperature.

- Packing: Apply hold pressure 30–60% of injection for 5–15 seconds.

- Cooling: The part cools inside the mold, solidifying into its final shape.

- Ejection: The mold opens and the finished part is removed.

Custom TPE Molding Solutions

Challenges in TPE Injection Molding Manufacturing Process

TPE injection molding encounters material-specific issues. Solutions maintain quality in thermoplastic elastomer molding.

Shrinkage and Warpage

Shrinkage and warpage occur when the TPE material cools unevenly, often due to differences in wall thickness or complex part geometries. To manage this, we need to optimize mold design to ensure uniform wall thickness throughout the part. Additionally, the cooling process should be controlled to avoid rapid temperature changes.

Flow Lines and Weld Lines

Weld lines form when different flow fronts meet in the mold cavity, often resulting in weak spots or surface imperfections. These issues can be mitigated by adjusting the injection speed and pressure. Improving the mold design, particularly the gating and runner systems, helps minimize flow interruptions. Additionally, optimizing the material distribution within the mold and ensuring proper cooling channels can help avoid these defects.

Material Sticking to Molds

TPE materials, especially softer or highly flexible grades, can sometimes adhere to the mold surface, making it difficult to eject the finished part. The solution lies in using appropriate mold release agents, which reduce friction and prevent sticking.

Air Traps and Bubbles

In TPE injection molding, air traps and bubbles often caused by trapped air or moisture within the mold during the injection process. To prevent this, it’s essential to ensure proper venting within the mold.

Flash and Burrs

Excess material escapes mold seams under high pressure and forms flash. The solution includes lower injection pressure, ensuring precise clamp tonnage, and clean mold surfaces regularly.

Material Degradation

Overheating will cause the chain to break down. The solutions include: limit residence time under 5 minutes, monitor barrel temperatures closely, and purge the machine between runs.

Applications of TPE Injection Molding

TPE serves multiple sectors through TPE injection molding and TPE overmolding.

- Automotive: Window seals, gaskets, interior grips.

- Consumer Goods: Tool handles, phone cases, buttons.

- Medical: Syringe stoppers, tubing.

- Electronics: Cable jackets, keypads.

- Industrial: Conveyor belts, vibration dampers.

- Sports: Shoe midsoles, equipment grips.

Differences Between TPE and Silicone

TPE and silicone are both elastomers, but they differ in processing and properties. The table below highlights key differences:

| Property | TPE | Silicone |

|---|---|---|

| Processability | Easy to injection mold | Requires compression or liquid molding |

| Elasticity | Good | Excellent |

| Temperature Resistance | -40–150°C | High (-60 to 230°C) |

| Chemical Resistance | Good | Excellent for acids and bases |

| Recyclability | Yes | No |

| Cost | Generally lower | Higher |

TPU vs TPE in Injection Molding

While TPU is a type of TPE, its properties differ slightly from general-purpose TPEs:

| Property | TPU | TPE (General) |

|---|---|---|

| Hardness | 70–95 Shore A | 30–80 Shore A |

| Tensile Strength | 25–60 MPa | 8–50 MPa |

| Abrasion Resistance | Excellent | Good |

| Processing Temp | 190–220°C | 150–230°C |

| Flexibility | Moderate | High |

| Cost | Higher | Medium |

Conclusion

TPE injection molding processes thermoplastic elastomers into flexible, recyclable parts. Grade selection and controls ensure performance in TPE molding and injection molding of elastomers. Zhongren provides TPE injection molding services, from prototyping to production.