Injection molding is a manufacturing process that produces precise plastic parts by injecting molten material into a mold cavity, where it cools and solidifies. This technique is widely used in industries such as automotive, electronics, medical devices, and consumer goods for its ability to create complex shapes in high volumes. Knowing the principle of injection molding helps identify potential defects, streamline designs, and ensure consistent output, making it a critical foundation for successful manufacturing. This guide explains the injection moulding working principle, key components, and influencing factors to provide clear insights for effective application.

Injection Molding Basic Principles

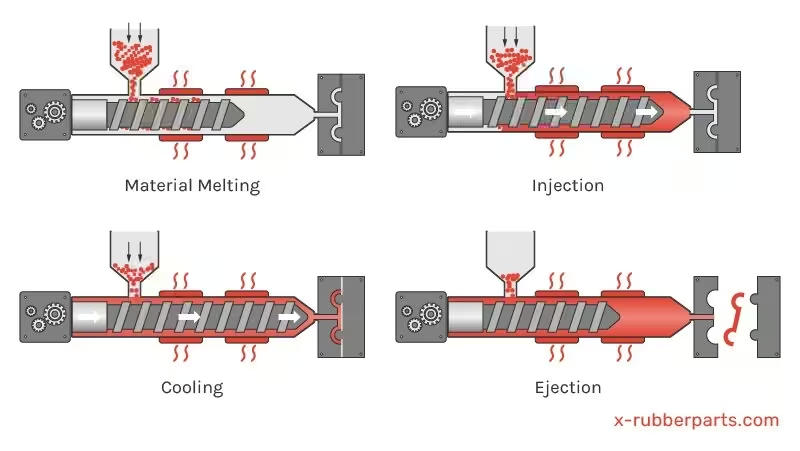

The principle of injection moulding process involves a controlled cycle of melting, injecting, cooling, and ejecting plastic to form precise parts. Below are the detailed steps outlining the working principle of injection moulding.

Raw Material Melting

The process begins with melting plastic pellets to create a flowable material. Pellets are fed from a hopper into a heated barrel, where a rotating reciprocating screw moves them forward. The screw, divided into feed, compression, and metering zones (compression ratio 2-4), generates friction and shear heat, while external heating bands maintain temperatures above the material’s melting point. Precise temperature control prevents degradation, ensuring uniform viscosity. Additives like glass fibers may be included to enhance strength, though they require careful management to avoid clogging. For customized material selection and formulation, explore our custom rubber molding services designed to optimize performance across various applications.

Injection Filling

In this phase, the molten plastic is injected into the mold cavity under high pressure. The screw advances, pushing the material through a nozzle and into the mold via a gate and runner system. Injection speed is controlled to fill the cavity evenly before the material begins to solidify, preventing defects like short shots. Air is expelled through vents to avoid trapped gas bubbles. The injection molding principles here focus on achieving complete cavity fill, influenced by material flow properties and mold design, ensuring the part’s structural integrity.

Packing and Cooling

After filling, packing pressure (50-80% of injection pressure) is applied to compensate for material shrinkage as it cools, ensuring a dense, accurate part. Cooling occurs through channels in the mold, circulating water or oil at controlled temperatures. Cooling time, often 60-80% of the cycle, depends on part thickness and material properties. Uniform cooling prevents warping or sink marks, while precise packing reduces shrinkage. This stage of the principle of injection molding is critical for dimensional accuracy and surface quality. For a deeper look at optimizing the cooling phase, refer to our cooling injection molding guide.

Ejection/Demolding

Once cooled and solidified, the mold opens, and the part is ejected using pins or plates. A draft angle on the part design ensures smooth release without damage. Ejection force is managed by the machine’s clamping unit, and cycle times range from 10-60 seconds. Post-ejection, parts are inspected, and waste like runners is recycled. Efficient ejection, a key aspect of the injection moulding working principle, supports high production rates and minimizes defects. Learn more about mechanism design in our ejection system injection molding article.

Key Components of Injection Molding Machines and Molds

The injection molding principles rely on the machine and mold systems to execute the process accurately. These components directly impact part quality and efficiency.

Injection Molding Machine System

The injection molding machine consists of a hopper for storing pellets, a heated barrel for melting, a reciprocating screw for mixing and injecting, a nozzle for transferring material to the mold, a hydraulic or electric drive for pressure and motion, a clamping unit to secure the mold, and a control system to monitor parameters. The screw ensures uniform melting, the drive delivers precise injection pressure, and the clamping unit (with forces up to hundreds of tons) maintains mold stability during packing. Modern machines use sensors and control systems to adjust temperature and pressure in real time, enhancing the working principle of injection moulding by ensuring consistency.

Mold System

The mold defines the part’s shape and supports the injection molding working principle by guiding material flow and cooling. Its components, such as gates and runners, manage material entry, while vents and cooling channels ensure defect-free parts. The table below details key mold components:

| Name | Location | Function | Appearance |

|---|---|---|---|

| Gate | Mold entry point | Controls material flow into cavity | Small circular or rectangular hole |

| Runner | Channel after gate | Distributes molten plastic to cavities | Linear or branched channel, round/trapezoidal |

| Cavity & Core | Inside mold | Shapes the final part (cavity for exterior, core for interior) | Smooth or textured negative space (cavity) and positive space (core) |

| Ejector Pins | Mold B-side | Pushes part out after cooling | Cylindrical metal pins |

| Slider & Lifter | Side/core sections | Ejects undercut or lateral features, assists part release | Movable blocks or plates guided by lifter mechanisms |

| Vent | Cavity edges | Releases air and gases | Narrow slots, 0.01-0.03mm wide |

| Cooling Channel | Within mold walls | Circulates coolant to control temperature | Internal spiral or linear pipes |

Key Factors Influencing Injection Molding

Several factors affect the injection molding, influencing the quality and efficiency of the process across the melting, filling, and cooling stages.

Material Properties

Melting points vary by resin requiring precise barrel temperature control to ensure proper melting without degradation. Flowability, determined by molecular weight and viscosity, affects injection speed and cavity fill. Shrinkage rates influence dimensional accuracy, as higher shrinkage can lead to undersized parts or sink marks.

Additives modify material behavior to meet specific needs. Glass fibers increase strength and stiffness but may reduce flowability and raise injection pressure requirements. Mineral fillers lower costs and reduce shrinkage, minimizing warping. UV stabilizers enhance durability for outdoor applications, while lubricants like PTFE improve flow, reducing cycle times. However, excessive additives can compromise properties, so careful formulation is needed to balance cost and performance. For integrated material support, you can explore our custom plastic manufacturing services.

Process Parameters

Parameters directly control the principle of the injection moulding process. Barrel temperature ensures proper melting, while mold temperature affects cooling. Injection speed prevents short shots, and pressure ensures proper packing. Cooling time, often 60-80% of the cycle, avoids warping. Fine-tuning these parameters will avoid defects such as sink marks, voids, or warpage. Real-time monitoring with sensors optimizes these settings for consistency. Holding pressure plays a decisive role in compensating for material shrinkage and achieving dimensional stability. Learn more in our injection molding holding pressure article.

Mold Design

Mold design shapes the part and process efficiency. Gate placement optimizes flow paths to avoid weld lines. Vents prevent gas entrapment. Uniform wall thickness reduces stress. Ejector pin placement ensures clean release. Undercuts require sliding cores, increasing complexity. Draft angles simplify ejection. DFM analysis early in design minimizes defects and aligns with injection molding.

Conclusion

Mastering the working principle of injection moulding will produce high-quality, cost-effective plastic parts. Understanding and applying the injection molding principles is the key to success in manufacturing. Zhongren provides injection molding services. We support customers with professional mold design, DFM analysis, material optimization, and stringent quality controls, ensuring defect-free parts and cost-effective production from small runs to high-volume runs.