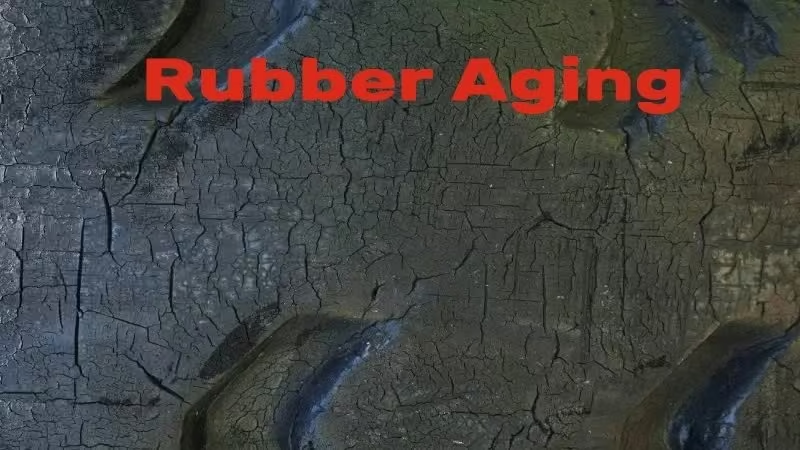

Rubber aging is a natural process that occurs as rubber materials are exposed to environmental factors, temperature variations, or chemicals. This leads to a decline in elasticity, strength, and durability. For molded rubber products, understanding the causes of aging and implementing preventive measures can significantly extend product lifespan and enhance performance.

What is Rubber Aging?

Rubber aging is the gradual deterioration of rubber materials caused by long-term exposure to heat, light, oxygen, ozone, mechanical stress, and chemicals. These environmental factors break down the polymer chains in rubber, leading to oxidation, cross-linking, and cracks. As a result, the material loses elasticity, flexibility, tensile strength, and resistance to wear, ultimately shortening its service life.

What Is the Shelf Life of Rubber?

The shelf life of a rubber material refers to the recommended duration it can be stored. This period varies depending on the type of rubber. The table below outlines the standard shelf life for different rubber materials.

| Rubber Material | Recommended Shelf Life |

|---|---|

| Natural Rubber | 3-5 years |

| Isoprene | 3-5 years |

| SBR | 3-5 years |

| Neoprene | 5-10 years |

| EPDM | 5-10 years |

| Butyl | 5-10 years |

| Nitrile | 5-10 years |

| Viton | 20 years |

| Silicone | 20 years |

What Causes of Rubber Ageing?

Ageing of rubber occurs due to a combination of natural factors that gradually affect the material’s performance. Here are the main causes of rubber aging:

Thermal Aging

High temperatures speed up rubber deterioration. When exposed to heat, rubber molecules react with oxygen, leading to the formation of free radicals that damage the structure of the rubber. This results in reduced elasticity, increased hardness, and a higher likelihood of cracking under stress.

Oxygen Exposure

Oxygen causes rubber to degrade over time by reacting with the rubber molecules, making the material harder and less flexible. This process reduces the overall lifespan of rubber products.

UV Light Exposure

Ultraviolet (UV) light, commonly from the sun, can cause rubber to break down by triggering chemical reactions in the material. This leads to surface cracks, discoloration, and a loss of strength, especially in products used outdoors.

Ozone Exposure

Ozone, found in the atmosphere, is highly reactive with rubber. It can cause rubber to develop cracks, especially in outdoor environments, which can lead to early-stage rubber deterioration exposed to high ozone concentrations.

Mechanical Stress

Repeated stretching, bending, or compressing of rubber can weaken it over time. This mechanical wear and tear, especially in products like seals, tires, and belts, leads to cracks and loss of functionality due to fatigue.

Chemical Exposure

Exposure to harsh chemicals, such as oils, solvents, and fuels, can break down rubber and cause it to swell, soften, or lose its strength. In environments where rubber is exposed to chemicals, the material can degrade faster.

What Are the Ways to Prevent Rubber Aging?

Preventing rubber aging involves implementing measures to minimize exposure to environmental factors and stressors that contribute to degradation. Here are several ways to prevent rubber aging:

Proper Storage & Handling to Prevent Rubber Aging

- Store rubber products in cool, dry, and well-ventilated areas away from direct sunlight, heat sources, and ozone-generating equipment.

- Use protective packaging, such as sealed bags or containers, to shield rubber materials from exposure to moisture, dust, and contaminants during storage and transportation.

- Handle rubber products with care to avoid excessive bending, stretching, or compression that can induce mechanical stress and accelerate aging.

Prevent Rubber Aging with Protective Coatings and Treatments

- Apply protective coatings, such as UV-resistant coatings or ozone-resistant coatings, to rubber surfaces exposed to sunlight or outdoor environments.

- Treat rubber materials with anti-oxidants, UV stabilizers, or ozone inhibitors to enhance their resistance to oxidative degradation and photo-oxidative aging.

Preventing Rubber Aging by Controlling Environmental Condition

- Control temperature and humidity levels in manufacturing facilities, storage areas, and operational environments to minimize thermal aging and moisture-related degradation of rubber materials.

- Install air filtration systems or ozone scrubbers in industrial settings to reduce ozone concentrations and mitigate ozone-induced aging of rubber components.

Rubber Aging Prevention Through Material Selection and Formulation

- Choose appropriate rubber materials and compounds designed for the intended application and environmental conditions.

- Select additives, fillers, and reinforcements that enhance the durability, UV resistance, and chemical compatibility of rubber materials.

- Optimize vulcanization processes and curing parameters to achieve the desired balance of mechanical properties and aging resistance in rubber products.

Regular Inspection and Maintenance of Rubber Components

- Implement routine inspection and maintenance schedules to detect signs of aging, wear, or degradation in rubber components.

- Replace aged or damaged rubber parts promptly to prevent potential failures, safety hazards, or performance issues in machinery, equipment, or infrastructure.

- Conduct periodic testing and evaluation of rubber materials using accelerated aging tests, such as heat aging, UV exposure, ozone exposure, and mechanical fatigue testing, to assess their long-term performance and durability.

Chemical Protection Measures for Rubber Aging Prevention

- Implement pollution control measures and environmental management practices to minimize exposure of rubber materials to harmful chemicals, solvents, and pollutants.

- Enhance production processes by optimizing curing and molding techniques to improve the chemical stability and aging resistance of rubber products.

Conclusion

While ageing of rubber is inevitable, its effects can be minimized with the right preventive actions. As a specialized provider of custom rubber molding services, we ensure high-quality products that perform reliably in various environments, offering both short-term solutions and long-term durability.

FAQ

How can I extend the service life of rubber products?

Many rubbers contain double bonds in their polymer chains, making them prone to degradation from oxygen and ozone. Adding antioxidants and antiozonants to the rubber compound can significantly improve its resistance and extend its service life.

Does contact with oil cause rubber to swell?

Yes, many types of rubber will swell or degrade when in prolonged contact with oil, especially mineral or petroleum-based oils. Choosing an oil-resistant rubber such as NBR or FKM can prevent this issue in oil-exposed applications.