Urethane Molding Service

Partnering for Excellence in Polyurethane Molding

If you are

looking for

Cost-effective molded urethane solutions

Customized molding urethane solutions

Tailored urethane molding expertise

Consistent quality

Precision and reliability

Expert guidance on material selection

Polyurethane Molding Process

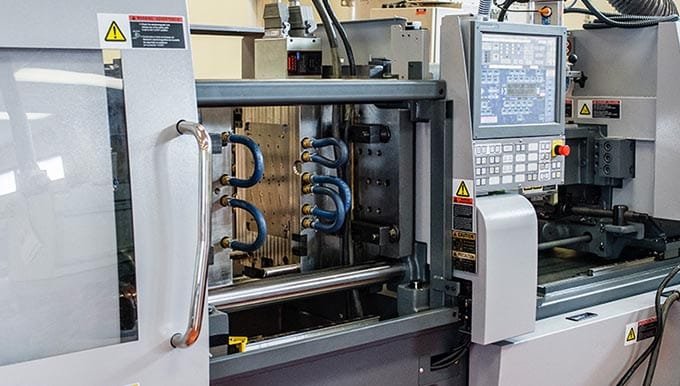

Polyurethane Injection Molding

Our advanced polyurethane injection molding process delivers high-quality, custom parts with exceptional dimensional accuracy and consistent repeatability. Whether for small batches or large-scale production, our expertise and technology ensure reliable solutions tailored to your exact specifications.

- Advantages

- Lower Tooling Costs

- Low Energy Usage

- Lightweight Yet Durable Parts

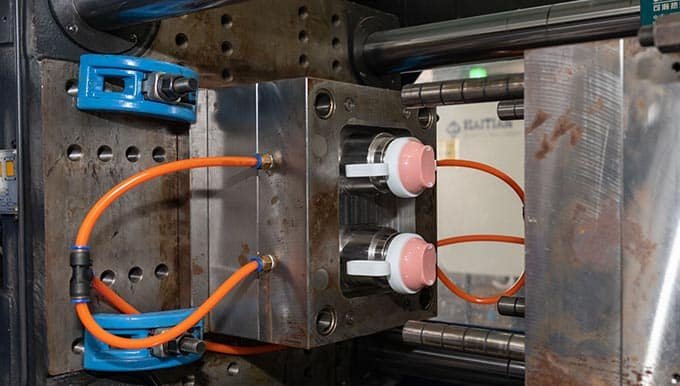

Urethane Cast Molding

- Advantages

- Metal and Non-Metal Bonding

- Variable Cross-Sections

- Save on Tooling and Part Costs

Custom Molded Urethane Parts

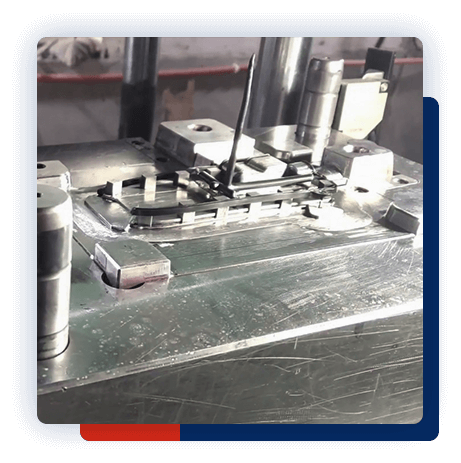

Our Quality Control

Material Selection

Before material enter production line, we carefully inspect their quality.

In-process Quality Checks

During the manufacturing process, technicians conduct regular quality checks to ensure consistency and adherence to specifications.

Final Inspection

After inspecting quality, functionality, and adherence to customer requirements, each product can be finished.

Molded Polyurethane Parts for Various Industries

Related Services

Rubber Molding

Rubber Bonding

Plastic Molding

Plastic Bonding

FAQs of Urethane Casting Service

Can polyurethane molded parts be customized for specific applications?

Yes, polyurethane molding allows for a high degree of customization. The material properties, hardness, shape, and size can be tailored to meet the unique requirements of different applications.

Is polyurethane material resistant to environmental factors like moisture, chemicals, and temperature extremes?

Polyurethane is known for its resistance to abrasion and wear, as well as its ability to withstand exposure to various environmental conditions. However, the specific formulation can influence these properties.

Are there any limitations to polyurethane molding, such as size constraints or material compatibility?

Polyurethane molding can accommodate a wide range of sizes, but there may be limitations on extremely large or complex parts. Material compatibility depends on the application and specific formulation.

How can I start a polyurethane molding project?

To get started, contact us through our website. We’ll provide a customized polyurethane molding solution based on your project’s requirements.