Thermoplastic Elastomer Molding

Your TPE Molding Specialist: Developing Quality Custom TPE Molding Components

We deliver durable, flexible, and custom-molded elastomer parts to meet your exact needs. Let our TPE expertise turn your product ideas into production-ready reality.

Types of TPE Moulding

TPE Injection Molding

TPE injection molding involves heating thermoplastic elastomer pellets until molten, then injecting them into a mold to form flexible tpe parts. This process is ideal for producing soft-touch grips, seals, gaskets, and other tpe components.

- Advantages

- Elasticity and Flexibility

- Durability

- Design Flexibility

TPE Overmolding

TPE overmolding is a process where molten thermoplastic elastomer is molded over a rigid substrate, such as plastic or metal, to create a single, bonded component. It’s ideal for producing ergonomic grips, soft-touch handles, buttons, and vibration-damping parts.

- Advantages

- Enhanced Grip

- Durability

- Seamless Bonding

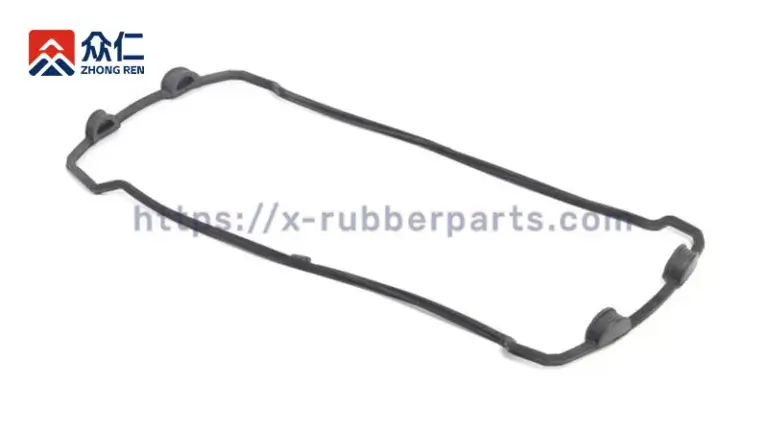

Thermoplastic Elastomer Molding Parts

Explore our product showcase to see real-world case studies of our custom TPE molding

Our Quality Control

At Zhongren, we are committed to delivering products of the highest quality through our robust quality control measures. With adherence to strict quality control standards, we ensure that every elastomer molding part meets rigorous criteria for performance, reliability, and customer satisfaction.

Material Selection

Before material enter production line, we carefully inspect their quality.

In-process Quality Checks

During the manufacturing process, technicians conduct regular quality checks to ensure consistency and adherence to specifications.

Final Inspection

After inspecting quality, functionality, and adherence to customer requirements, each product can be finished.

TPE Moulding for Various Industries

Related Services

Plastic Molding

Our plastic molding service shapes plastic materials into desired forms or products by applying heat and pressure.

Plastic Bonding

Our plastic bonding service providing seamless connections between plastic and metal.

Rubber Bonding

Our rubber bonding service providing seamless connections between rubber and metal, rubber and plastic.

Urethane Molding

Our urethane molding service involves casting liquid polyurethane into a mold to create pu parts.

FAQs of TPE Moulding

If you have more questions, please move to our FAQ page.

Can TPE molded parts be painted or coated?

Yes, TPE molded parts can be painted or coated, but the adhesion of coatings may vary depending on the TPE formulation and surface characteristics. Surface preparation and the choice of compatible coatings are essential to ensure proper adhesion and long-term durability.

What post-processing options are available for TPE molded parts?

Post-processing options for TPE molded parts may include trimming, deburring, welding, assembly, pad printing, and additional surface finishing techniques. These post-processing steps help achieve the desired final appearance and functionality of the TPE parts.

What factors should be considered when working with TPEs?

When working with TPEs, factors such as melting temperature, pressure, mold design, and the specific physical properties of the chosen TPE grade should be carefully considered to ensure successful processing and high-quality parts.

How can I get started with a TPE moulding project?

You can contact us, send us drawings to discuss your project, and get started with your TPE moulding requirements.