Custom Rubber Mouldings

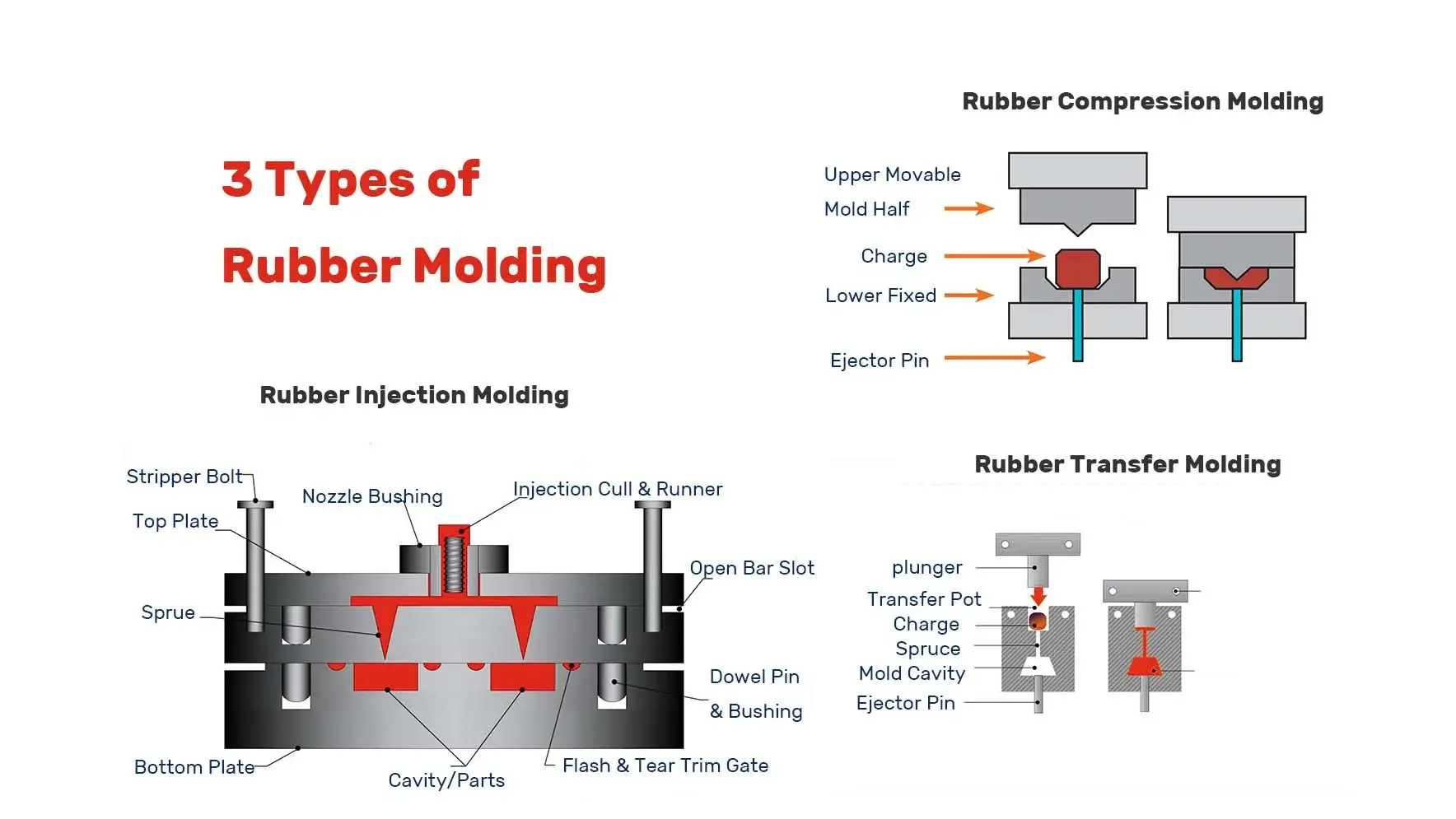

Types of Rubber Moldings

Rubber Compression Molding

Rubber compression molding is a reliable and cost-effective method for producing medium to large rubber parts with simple to moderately complex shapes. By applying high pressure to a preheated rubber compound inside a mold cavity, this process ensures excellent product consistency, dimensional stability, and surface finish. It is ideal for manufacturing durable, high-quality moulded rubber components used in various industrial applications.

- Advantages

- Cost-effectiveness

- Dimensional accuracy

- Material versatility

Rubber Injection Molding

- Advantages

- Precision and Accuracy

- Complex Part Designs

- Efficient Material Usage

Rubber Transfer Molding

- Advantages

- Complex Part Designs

- Reduced Waste

- Shorter Cycle Times

Rubber Mouldings Material Options

Rubber Material

1、Natural Rubber (NR)

2、Styrene Butadiene Rubber (SBR)

3、Nitrile Rubber (NBR)

4、Ethylene Propylene Diene Monomer (EPDM)

5、Silicone Rubber(MVQ)

6、Neoprene Rubber (CR)

7、Butyl Rubber (IIR)

8、Polyurethane Rubber (PU)

9、Fluoroelastomers (FKM)

Additives

1、Carbon Black - Reinforcement

2、Silica - Reinforcement and Abrasion Resistance

3、Clay - Reinforcement and Processability

4、Plasticizers - Flexibility Enhancement

5、Antioxidants - Oxidation Resistance

6、Accelerators - Curing Agent

7、UV Stabilizers - UV Protection

8、Flame Retardants - Fire Resistance

9、Anti-static Agents - Static Control

When choosing a rubber mouldings material, the most important factor to consider is adaptability to the various environment, ensuring that the materials have outstanding performance to meet your needs.

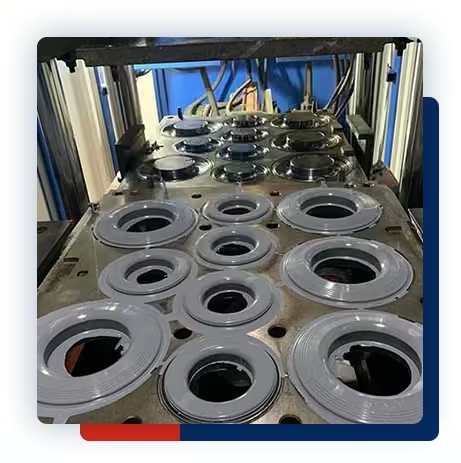

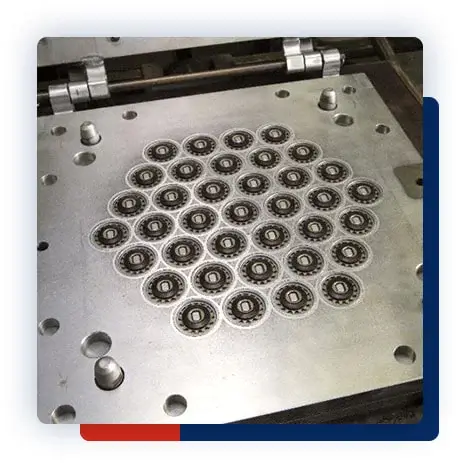

Custom Molded Rubber Components

Our Quality Control

Material Inspection

Before material enter production line, we carefully inspect their quality.

In-process Quality Checks

During the manufacturing process, technicians conduct regular quality checks to ensure consistency and adherence to specifications.

Final Inspection

After inspecting quality, functionality, and adherence to customer requirements, each product can be finished.

Rubber Molding for Various Industrial

Related Services

Plastic Molding

Plastic Bonding

Rubber Bonding

Urethane Molding

FAQs of Rubber Moldings

Do you provide custom rubber moldings solutions?

Yes, we offer tailored rubber molding solutions to meet the unique needs of our clients across different industries.

What kinds of rubber materials do you work with?

We specialize in working with a wide range of rubber materials, including natural rubber, silicone rubber, EPDM, NBR, and more.

What is the typical lead time for rubber molding projects?

Lead times can vary depending on the complexity and volume of the project. We work closely with our clients to provide accurate estimates for each project.

How can I request a quote or get started with a rubber molding project?

You can start from the Get a Quote page, send us drawings to discuss your project, and get started with your rubber molding requirements.