Custom TPE Molding Product

Custom Thermoplastic Elastomer Molding Solution

Zhongren specializes in TPE injection molding, delivering high-quality thermoplastic elastomer parts for the medical, consumer goods, automotive, and electronics sectors. With deep expertise in thermoplastic elastomer molding, we ensure excellent part consistency, dimensional accuracy, and aesthetic appeal. TPE molding enables fast, cost-effective production of soft-touch, overmolded, lightweight, and flexible components. Its wide hardness range and recyclability make it a sustainable alternative to traditional rubber for many applications.

How Are Thermoplastic Elastomer Parts Manufactured?

We use several advanced injection molding elastomers technologies to manufacture high-quality TPE parts, depending on your requirements:

- TPE Injection Molding

- TPE Overmolding

- Insert Molding with TPE

- TPE Extrusion Molding

Key process factors include material selection, tool design, and temperature control to ensure optimal bonding and part performance.

Common Applications of TPE Molding Products

Thanks to its versatility and comfort, TPE moulding is ideal for ergonomic, soft-touch, or high-flex applications:

- Medical tubing and seals

- Grips and handles

- Electrical cable grommets

- Appliance seals

- Toys and baby products

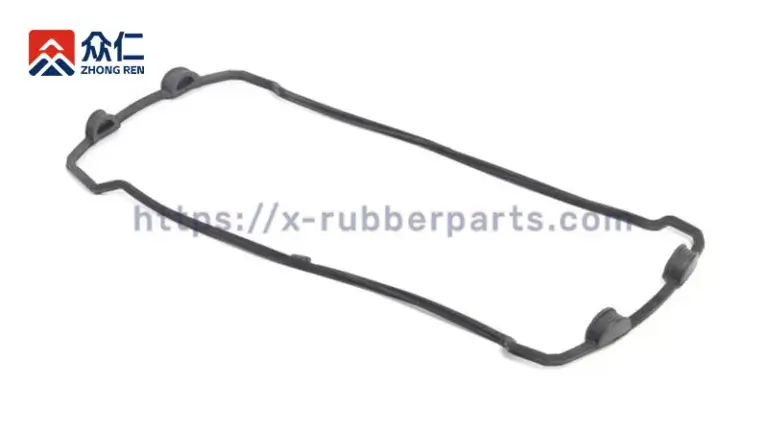

- Automotive gaskets and mats

Our Valued-Added Services

- Design and Engineering Support

- Material Testing and Certification

- Surface Finishing and Printing

- Assembly and Sub-Assembly

- Custom Packaging and Labeling

Advantages of TPE Molding

- Recyclable and environmentally friendly

- Wide hardness range (Shore A to Shore D)

- Good chemical and UV resistance

- Excellent flexibility and elasticity

- Cost-effective and fast-cycle processing

- Ideal for overmolding and multi-material parts

Disadvantages of TPE Molding

- Lower heat resistance than thermoset rubbers like silicone

- May deform under high load and temperature

- Less durable in harsh chemical environments

- Lower tensile strength than vulcanized rubbers

FAQ with TPE Molding

Can TPE be overmolded onto plastic or metal?

Yes. TPE is ideal for overmolding on substrates like PP, ABS, PC, and certain metals using compatible adhesion techniques.

Is TPE safe for medical or food applications?

What hardness options are available for TPE?

TPE materials range from soft (Shore A 20) to semi-rigid (Shore D 50), customizable based on part requirements.

How does TPE compare to rubber?

TPE offers the feel and flexibility of rubber with the processability of plastic. It’s ideal for high-volume production and recyclable parts, while traditional rubbers offer better performance in extreme environments.

How does TPE compare to silicone?

TPE is easier to process, more cost-effective, and recyclable, while silicone offers superior high-temperature resistance and long-term durability. Unlike silicone, TPE melts when heated and can be remolded. Silicone requires vulcanization and is harder to recycle, but performs better in extreme environments.