What makes a gasket effective under pressure, heat, or chemical exposure? In this guide, we cover the essentials of gaskets, from how they differ from seals to how to choose the right material for your application.

What Is a Gasket?

A gasket is a flexible sealing component placed between two stationary surfaces to prevent the leakage of liquids or gases. It fills surface irregularities and maintains a tight seal under compression. Gaskets are commonly used in mechanical assemblies to ensure reliable, long-term sealing performance in static applications.

What’s the Difference Between Gaskets and Seals?

Although both serve to prevent leakage, gaskets and seals differ significantly in application, design, materials, and maintenance:

| Comparison Category | Gasket | Seal |

|---|---|---|

| Application Type | Static sealing between two flat, stationary surfaces | Dynamic sealing between moving parts (e.g., shafts) |

| Usage Location | Flanges, casings, pipe joints | Pumps, rotating shafts, pistons, hydraulic systems |

| Materials | Cork, rubber, graphite, PTFE, metal sheets | Rubber, silicone, polyurethane, metal lips, springs |

| Structure & Shape | Simple flat shape, easy to cut or punch | Complex geometry with lips, springs, or supports |

| Durability | No friction; performance depends on compression and chemicals | Handles friction and movement; higher wear resistance required |

| Cost & Maintenance | Lower cost, easy to replace | Higher cost, replacement usually requires disassembly |

| Typical Applications | Pipe flanges, engine heads, compressors | Hydraulic systems, rotating shafts, automotive oil seals |

What Are the Benefits of Using Gaskets?

- Provide reliable sealing and prevent leakage

Gaskets create a seal by filling microscopic gaps between mating surfaces, helping to prevent the escape of liquids or gases. - Perform well under various pressure and temperature conditions

With a wide selection of materials available, gaskets can maintain performance in high-temperature, high-pressure, or vacuum systems. - Offer strong resistance to chemical corrosion

Materials such as PTFE or graphite make gaskets suitable for harsh environments by withstanding acids, alkalis, oils, and solvents. - Improve system reliability

A well-installed gasket ensures long-term sealing at joints or flanges, reducing the risk of leaks and equipment failure. - Reduce maintenance frequency and equipment downtime

Durable gaskets extend service life, which helps cut maintenance costs and minimize production interruptions caused by repairs. - Absorb vibration and cushion mechanical impact

Flexible rubber gaskets can dampen vibration, reduce noise, and protect mechanical components from stress and fatigue.

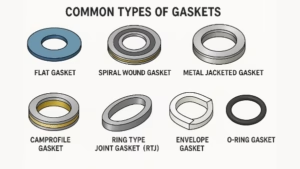

Common Types of Gaskets

Flat Gasket

Made from rubber, paper, or fiber, flat gaskets are simple and cost-effective, ideal for low-pressure static sealing with smooth flange surfaces, common in HVAC and low-pressure piping.

Spiral Wound Gasket

Constructed from spirally wound metal strips and soft filler, these gaskets offer excellent elasticity and high temperature-pressure resistance, widely used in oil, chemical, and power industry flange connections.

Metal Jacketed Gasket

Featuring a metal shell enclosing soft filler, these gaskets combine strength with sealing ability, suited for medium to high temperatures and corrosive environments like heat exchangers and boilers.

Camprofile Gasket

With a corrugated metal core covered by soft sealing material, camprofile gaskets seal effectively at low bolt loads and are used in high temperature and pressure applications in chemical and power plants.

Ring Type Joint Gasket (RTJ)

Solid metal ring gaskets designed for extreme pressure and temperature, creating a metal-to-metal seal to prevent leaks, commonly used in oil and gas pipelines.

Envelope Gasket

Consisting of a PTFE outer shell with flexible filler inside, envelope gaskets provide excellent chemical resistance and sealing, ideal for chemical, pharmaceutical, and food industries.

O-Ring Gasket

Circular rubber seals used in static and dynamic applications, easy to install and reliable, found in hydraulic, pneumatic systems, and automotive engines.

Common Gasket Materials

Different materials offer varying resistance to temperature, chemicals, and pressure, making selection critical for each application.

Rubber Materials

- Neoprene

Neoprene offers good weather, ozone, and moderate oil resistance. It is widely used in water pumps, HVAC systems, and general industrial sealing.

- Nitrile Rubber (NBR)

NBR has excellent resistance to oil, fuel, and abrasion, making it suitable for automotive fuel systems, hydraulic seals, and machinery gaskets.

- EPDM

EPDM molding provides outstanding resistance to steam, hot water, ozone, and UV, commonly used in outdoor systems, boilers, and HVAC duct seals.

- Silicone Rubber

Molding silicone handles extreme temperature ranges and is soft, non-toxic, and odorless. It is ideal for food-grade equipment, medical devices, and electronics.

- Viton® (Fluoroelastomer)

Viton® excels in high-temperature and chemical environments, making it ideal for petrochemical plants, aerospace, and engine gaskets.

Other Non-Rubber Materials

- PTFE (Polytetrafluoroethylene)

PTFE is chemically inert, withstands high temperatures, and resists contamination, widely used in pharmaceutical, chemical, and food industries.

- Flexible Graphite

This material withstands extreme temperatures and pressure, with excellent compressibility, used in boilers, steam valves, and flange seals.

- Mica

Mica gaskets resist high temperatures and provide excellent electrical insulation. They are used in power generation, furnaces, and metallurgy.

- Non-Asbestos Fiber

A reinforced fiber bonded with rubber, it offers good pressure and temperature resistance while being asbestos-free, ideal for flange sealing.

Key Selection Considerations for Gasket Materials

Temperature Range: Consider the temperature range of the application, including both operating and intermittent temperatures. Choose a gasket material that can withstand the temperature extremes without losing its sealing properties or deforming.

Chemical Compatibility: The gasket material must be chemically resistant to the fluids or gases it will be in contact with, such as acids, alkalis, oils, solvents, and other chemicals.

Pressure Range: Different gasket materials can withstand varying pressure levels. Metallic gaskets are suitable for high-pressure applications, while non-metallic gaskets like rubber are better for low to medium pressures. Ensure that the selected material can handle the pressure without extrusion or blowout, which can lead to leakage.

Environmental Factors: Consider the specific application environment such as exposure to UV radiation, ozone, weathering, and other environmental conditions, especially for outdoor applications. Materials like EPDM and neoprene exhibit good weather and ozone resistance.

Compressibility and Resilience: Assess the compressibility and resilience of the gasket material. The material should be able to conform to mating surfaces under compression to create a tight seal. Additionally, it should have the resilience to maintain its sealing properties over time and under varying pressures.

Industry Standards and Regulations: Certain industries like food and beverage or pharmaceutical may require gaskets made from FDA-compliant materials like EPDM or silicone.

Cost and Application Requirements: While performance is important, cost and application-specific requirements like ease of installation, reusability, and maintenance should also be evaluated.

What Is Gasket Used For?

Automotive Industry

Gaskets are critical in automotive applications, sealing engine components such as cylinder heads, exhaust systems, and oil pans. They prevent coolant, oil, and combustion gases from mixing or leaking, ensuring optimal engine performance and emissions control.

Oil and Gas Industry

Equipment in the oil and gas sector faces extreme temperatures, high pressures, and aggressive chemicals. Gaskets such as ring-type joint and spiral wound types are used in pipelines, refinery units, and pressure vessels to maintain high-integrity seals that prevent leaks and ensure safety.

Power Generation and Energy Industry

In power plants including thermal and nuclear stations, gaskets seal critical components like steam pipes, heat exchangers, and boiler assemblies. Their resilience to high pressure and thermal cycling ensures continuous operation and minimizes downtime for maintenance.

Chemical and Pharmaceutical Industries

These industries demand gaskets that resist corrosive or high-purity media. Materials such as chemically inert PTFE or pharmaceutical-grade elastomers are used in reactors, piping, and heat recovery systems to prevent leakage while maintaining compliance with hygiene standards.

Food and Beverage Industry

High sanitation requirements in food processing call for gaskets made from food-grade silicone or PTFE. They are installed in tank lids, conveyor lines, and packaging systems to ensure effective sealing and cleanability, preventing cross-contamination.

Marine and Offshore Industry

Marine and offshore equipment endures harsh conditions such as saltwater exposure, vibration, and pressure differentials. Gaskets, particularly metallic and semi-metallic types, are utilized in hull penetrations, piping interfaces, and engine systems for durable and corrosion-resistant sealing.

Medical and Laboratory Equipment

In medical and laboratory environments, gaskets are used in IV connectors, sterile piping, and chamber doors. They are made from FDA or ISO compliant materials that sustain airtight seals while ensuring sterility and contamination protection.

How to Choose the Right Gasket?

When selecting a gasket, the first step is to clearly define the operating conditions, including media type, temperature, and pressure. The material must be compatible with all of these factors. For example, chemical systems may involve aggressive media, while power generation requires resistance to both high heat and pressure.

Flange characteristics also matter. Parameters such as surface finish, bolt torque, and gasket size affect compression behavior and sealing effectiveness. Improper selection may lead to uneven load distribution and sealing failure.

Material reliability under long-term conditions is equally important. Properties like thermal stability, chemical resistance, and creep recovery must be considered, along with relevant certifications for safety and compliance in specific industries.

Finally, choose a gasket supplier with strong capabilities in design, manufacturing, and testing. Zhongren is well-versed in customizing gasket solutions across various industries and can provide precise recommendations based on your application needs.

FAQs

What are common causes of gasket failure, and how to fix them?

Typical issues include leakage, under-compression, creep, or material degradation. Solutions involve retorquing bolts, selecting more resilient materials (e.g., high-recovery rubber, spiral-wound gaskets, flexible graphite), and checking flange condition and installation quality.

My system experiences rapid temperature and pressure changes. What type of gasket should I use?

Choose gaskets with excellent thermal cycling and elasticity, such as spiral wound gaskets or flexible graphite, which can accommodate frequent stress changes without compromising the seal.

Are all gasket materials resistant to corrosive chemicals?

No, compatibility varies. PTFE is highly chemical-resistant in most environments, but in high-pressure systems, reinforced or jacketed PTFE may be necessary for safety and durability.