Rubber molding process is essential for producing durable, precision-engineered rubber parts. This article explores the three main types of rubber molding processes to help you choose the best method for your application.

What is Rubber Molding?

Custom rubber moulding is a manufacturing process used to shape rubber into custom parts by placing it into a mold cavity under heat and pressure. It allows for precise, repeatable production of complex rubber components used in industries like automotive, medical, and consumer goods.

3 Types of Rubber Molding Process

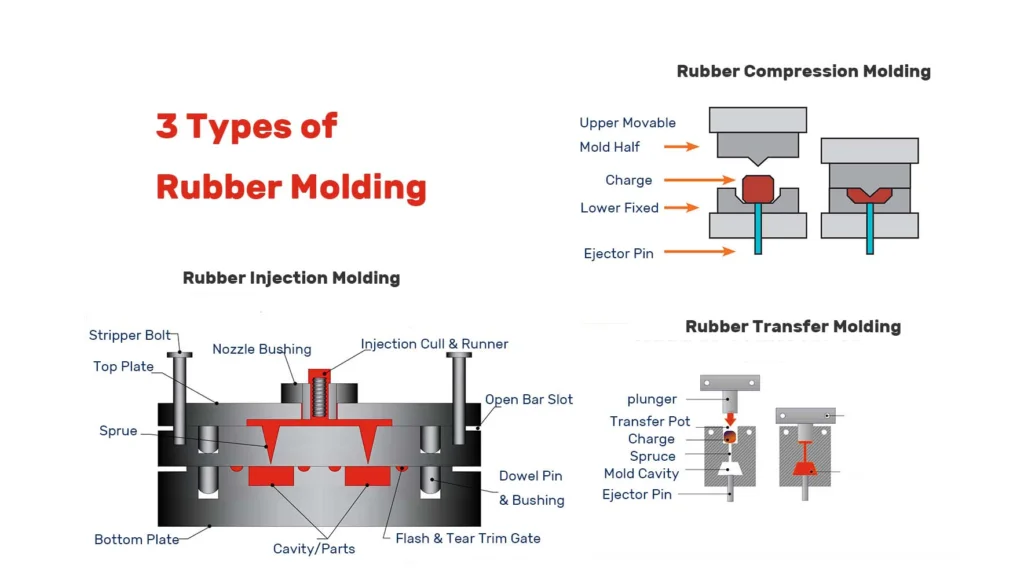

There are several types of rubber molding processes, each with distinct techniques and applications. This section highlights the three most common rubber moulding methods: compression molding process, transfer molding, and injection molding manufacturing.

Rubber Injection Molding

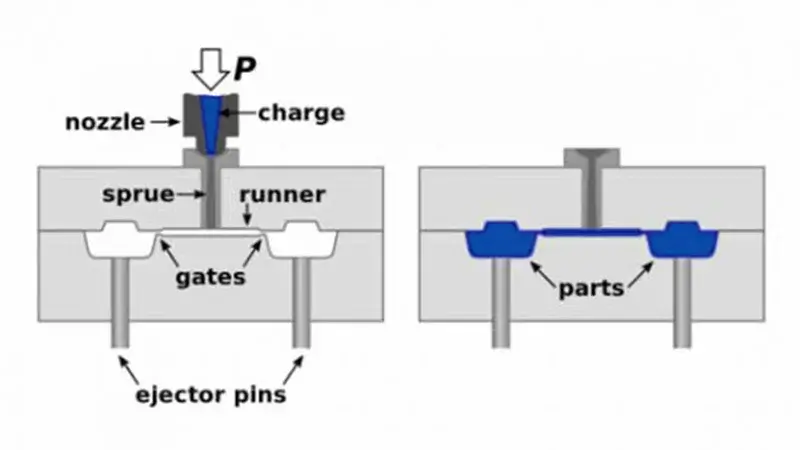

Rubber injection molding is a manufacturing process where uncured rubber is heated and injected into a precisely designed mold cavity under high pressure to form rubber products of desired shapes and sizes.

The Key Rubber Injection Molding Steps

- Uncured rubber is fed into the heated barrel of an injection molding machine.

- The rubber is plasticized and heated to a liquid state.

- The liquid rubber is injected under high pressure into a heated mold cavity through runners and gates.

- The rubber is cured and solidified inside the mold cavity, taking the shape of the mold.

- Once cured, the molded rubber part is ejected from the mold cavity.

Rubber Injection Molding

Rubber Injection Molding Advantages

Rubber injection molding offers several key advantages over other rubber molding methods:

High production rates: Injection molding is highly automated, allowing for faster cycle times and higher production volumes compared to compression or transfer molding. This makes it ideal for mass manufacturing of rubber parts.

Complex part geometries: The high injection pressures allow the rubber to flow into intricate mold details, enabling the production of parts with complex shapes, undercuts, and tight tolerances. This is difficult with compression molding.

Automation and consistency: The automated injection process ensures consistent part quality, dimensional accuracy, and reduced labor costs over many production cycles.

Versatility: Injection molding can process a wide range of rubber materials including natural rubber, liquid silicone rubber (LSR), and thermoplastic elastomers.

Long mold life: Injection molds, especially those made of steel, have a longer service life compared to compression or transfer molds, reducing tooling costs over higher production volumes.

Minimal post-processing: The high-quality surface finish achieved often eliminates the need for secondary finishing operations like trimming or polishing.

Rubber Injection Molding Disadvantages

The main disadvantages of rubber injection molding compared to other rubber molding methods:

Higher initial setup costs: Injection molding requires costly machinery and complex molds with features like runners, gates, and cooling systems, making it more expensive upfront than compression molding.

Longer lead times: Designing, testing, and producing injection molds can take several weeks or months, especially for complex parts. Compression molds are simpler and faster to produce.

Difficulty with design changes: Any design change in an injection molded part often requires creating a completely new mold, adding significant cost and delay. Design changes are easier with compression molds.

Rubber Injection Molding Applications

Rubber injection molding has a wide range of applications across various industries due to its ability to produce high-precision, complex parts with minimal waste. Some key productions of rubber injection molding include:

Seals and O-rings: Used in automotive, aerospace, industrial, and fluid power applications for sealing fluid and gas systems.

Gaskets: Found in automotive engines, machinery, and equipment to prevent fluid or gas leakage between mating surfaces.

Bushings and Mounts: Provide vibration isolation and shock absorption in automotive suspension systems, machinery, and equipment.

Diaphragms: Used in valves, pumps, and actuators to control fluid flow or pressure.

Rubber Keypads: Found in electronic devices such as remote controls, keypads, and medical equipment for tactile feedback and user interface.

Rubber Grips and Handles: Used on tools, appliances, sporting goods, and consumer products for ergonomic comfort and grip.

Medical Device Components: Including tubing, seals, gaskets, and diaphragms for medical devices and equipment such as infusion pumps, respirators, and diagnostic instruments.

Silicone Kitchenware: Such as spatulas, baking mats, molds, and oven mitts for food preparation and baking.

Rubber Grommets and Bumpers: Used in automotive, aerospace, and industrial applications for wire routing, cable protection, and impact absorption.

Silicone Baby Products: Such as pacifiers, bottle nipples, teethers, and feeding utensils for infants and toddlers.

Rubber Injection Molding Applications

Rubber Compression Molding

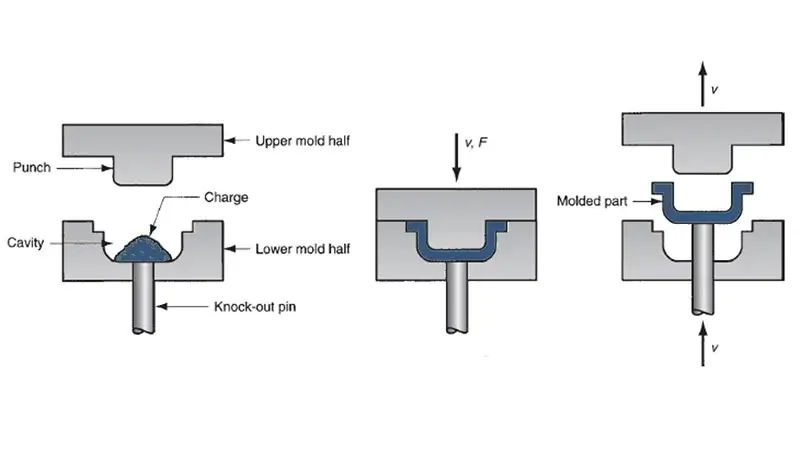

Rubber compression molding is a manufacturing process where uncured rubber is formed into a desired shape by applying heat and pressure between two heated mold cavities.

The Key Rubber Compression Molding Steps:

- An uncured rubber compound is formed into a preform or preheated shape based on the desired final part configuration.

- The preform is placed into the heated cavity of a compression mold.

- The mold is closed, and high pressure is applied to the preform, forcing it to conform to the mold cavity shape while being heated.

- After curing under heat and pressure, the mold is opened, and the molded rubber part is removed.

- Post-molding operations like deflashing, trimming, inspection, and packaging may be performed.

Rubber Compression Molding Advantages

Compared to other rubber molding processes like injection molding and transfer molding, the key advantages of rubber compression molding are:

Lower tooling costs: Compression molds are simpler and less expensive to manufacture compared to injection molds. That makes it a preferred choice for low to medium-volume production runs.

Suitable for large and thick parts: Since the material is directly loaded into the mold cavity, compression molding can handle larger amounts of material to make bigger parts.

Minimal material waste: Compression molding places rubber directly into the mold cavity, avoiding excess material from sprues or runners like in injection molding.

Rubber Compression Molding Disadvantages

Compared to other rubber molding processes like transfer molding and injection molding, the key disadvantages of rubber compression molding are:

Higher labor costs: Compression molding is more labor-intensive and less automated than transfer or injection molding, making it costlier for high-volume production.

Slower cycle times: The heating and curing process in compression molding is slower compared to injection molding. This limits the production rates that can be achieved.

Limitations in complex designs: The flow of material in compression molding can be restricted, making it unsuitable for parts with intricate details or complex geometries.

Not ideal for high-volume production: While cost-effective for low to medium volumes, the slower cycle times and higher labor costs make compression molding less economical for high-volume manufacturing compared to transfer or injection molding.

Rubber Compression Molding Applications:

Rubber compression molding is a widely used process for manufacturing various rubber products. Here are some common products produced using rubber compression molding:

Seals and Gaskets: Commonly used in automotive, aerospace, and industrial equipment, these components prevent fluid or gas leakage between mating surfaces.

O-Rings: Widely used in automotive, aerospace, and hydraulic systems, O-rings provide reliable sealing to prevent fluid or gas leakage in high-pressure environments.

Bushings and Grommets: Applied in automotive, electrical, and industrial equipment, they act as vibration dampers, isolators, and protective pass-throughs for wires and components.

Custom Molded Parts: Found in automotive, medical, and aerospace systems, custom parts like diaphragms, bellows, and boots serve sealing, protection, and motion control functions.

Rubber Dampers and Mounts: Used in vehicles, machinery, and HVAC systems, these components absorb shock and vibration to enhance stability and reduce noise.

Rubber Pads and Feet: Common in furniture, appliances, and electronics, rubber pads and feet offer anti-slip support, impact cushioning, and surface protection.

Rubber Rollers and Wheels: Used in conveyors, printers, and material handling equipment, rubber rollers and wheels provide traction, durability, and shock resistance.

Rubber Flooring and Mats: Applied in gyms, factories, and playgrounds, these products deliver slip resistance, impact absorption, and long-term wear protection in high-traffic areas.

Rubber Transfer Molding

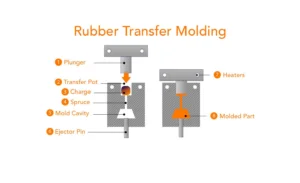

Rubber transfer molding is a manufacturing process where preformed uncured rubber is heated and forced under pressure into a heated mold cavity through sprues and runners.

The Key Rubber Transfer Molding Steps:

- Uncured rubber is preformed into a basic shape based on the desired final part.

- The preformed rubber is loaded into a pot or well located between the top plate and a plunger in the transfer mold.

- The mold is closed, and the plunger compresses and transfers the heated rubber through sprues and runners into the mold cavities below.

- Under heat and pressure, the rubber cures and takes the shape of the mold cavities.

- Once cured, the molded rubber parts are ejected from the cavities.

Rubber Transfer Molding Advantages

Higher Production Rates and Shorter Cycle Times: Transfer molding generally allows for faster cycle times than compression molding, enabling higher production volumes and increased efficiency.

Intricate Designs: Transfer molding enables the production of parts with sharper edges, more complex geometries, and tighter dimensional tolerances compared to compression molding, making it suitable for intricate designs.

Better Material Utilization: Transfer molding typically uses material more efficiently, resulting in minimal waste compared to other processes like compression molding. This can lead to cost savings and improved sustainability.

Reduced Post-processing: Parts produced via transfer molding often require less trimming and post-processing work, saving time and labor costs in the manufacturing process.

Automated Production and Lower Labor Costs: Transfer molding can be easily automated, reducing the need for manual labor and lowering production costs, especially for high-volume production runs.

Design Flexibility: Transfer molding supports insert and multi-component molding, enabling integration of different materials or parts into one product for greater functionality and cost efficiency.

The Main Rubber Transfer Molding Disadvantages

Compared to other rubber molding processes like compression molding and injection molding, the key disadvantages of rubber transfer molding are:

Higher tooling costs due to more complex molds: Transfer molds require intricate designs with transfer pots, plungers, and gating systems, making them more expensive than simple compression molds.

Need for more frequent mold maintenance: The inserted transfer tools require regular maintenance to ensure proper movement and alignment over time. This can involve time-consuming cleaning and resetting of inserts.

Limitations in large parts: Transfer molding is best suited for small to medium-sized parts due to limitations in press sizes, unlike injection molding which can produce much larger parts.

The Rubber Transfer Molding Applications

Electrical connectors and components: Transfer molding facilitates the molding of rubber over metal or plastic inserts, making it suitable for producing electrical connectors, spark plug wires, and other electrical components.

Seals and gaskets: Transfer molding is widely used to produce various seals and gaskets like O-rings, valve seals, static seals, and gaskets for automotive, aerospace, and industrial applications.

Hydraulic and pneumatic components: The process allows for sharper cutoffs and defined edges, making it ideal for producing lip seals, U-cup seals, and other hydraulic/pneumatic components.

Diaphragms and bellows: The ability to produce complex shapes with tight tolerances makes transfer molding suitable for manufacturing diaphragms and bellows used in various industries.

Composite seals and multi-component parts: Transfer molding enables the production of composite seals and multi-component parts by molding rubber over metal or plastic inserts, reducing overall component counts.

Which Type of Rubber Molding Is Right for Your Application?

Choosing the right rubber molding process depends on several key factors, including part complexity, production volume, tooling cost, and material efficiency.

- For simple shapes, large or thick parts, or low-volume production, compression molding is cost-effective and ideal for prototyping.

- If your design includes metal or plastic inserts, requires moderate to high precision, and you’re planning medium production runs, transfer molding offers a strong balance between flexibility and cost.

- For intricate geometries, thin walls, or high-volume production, injection molding delivers the best results with excellent consistency and speed—perfect for automotive, medical, and consumer goods.

Additional considerations include tooling investment and material waste. Compression molds are the least expensive and waste very little. Transfer molds offer greater control but produce some scrap. Injection molding requires the highest upfront cost but ensures the tightest tolerances and fastest throughput.