As a type of rubber molding process in modern manufacturing, transfer molding is used to produce molded rubber parts and plastic parts. In this post, we’ll delve into transfer molding, exploring its principles, process steps, and applications across various industries.

As a type of molding process in modern manufacturing, transfer molding is used to produce molded rubber parts and plastic parts. In this post, we’ll delve into transfer molding, exploring its principles, process steps, and applications across various industries.

What is Transfer Molding?

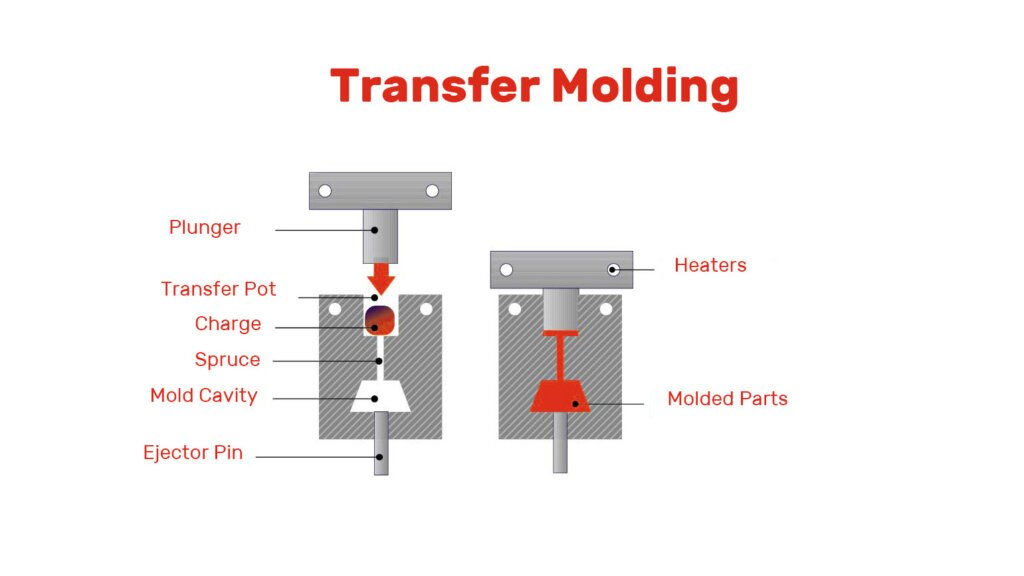

Transfer molding is a precision molding method where preheated material is forced through a plunger into a closed mold cavity via sprues and runners. It combines advantages of compression and injection molding for high‑quality elastomer and thermoset parts.

Transfer Molding Steps

Materials Preparation

The raw material, typically a thermoset resin, is converted into powder, pellets, or granules. Additives like colorants, plasticizers, and stabilizers may be mixed in to achieve desired properties. The molding material is heated to a predetermined temperature.

Loading the Materials into the Transfer Pot:

The heated molding compound is loaded into the transfer chamber or pot. The mold is cleaned and coated with a release agent to prevent sticking.

Closing the Mold:

The mold is closed and secured tightly. A plunger in the transfer pot pushes the molding compound through the sprue and into the mold cavity.

Applying Heat and Pressure:

Continuous heat and pressure are applied to the closed mold to cure the resin. Uniform heating across the mold is important for consistent curing.

Filling the Mold:

The heat and pressure force the molding compound to flow and fill the mold cavity uniformly.

Curing the Material:

The heated and pressurized material undergoes a chemical transformation (cross-linking and polymerization) to take the shape of the mold. Curing parameters like time, pressure, and temperature are controlled.

Opening the Mold:

After curing, the plunger returns to its initial position, releasing the pressure. The mold halves open, and the finished part is ejected, often with the help of ejector pins.

The Advantages of Transfer Molding

Transfer molding offers several advantages over other molding techniques, making it a preferred choice for some specific applications.

Reduced Cycle Times:

Transfer molding typically involves shorter cycle times compared to processes like compression molding. The preheating of materials and mold, coupled with controlled material transfer and curing, allows for faster production rates. This efficiency translates to increased productivity and lower manufacturing costs.

Design Flexibility:

Transfer molding allows for sharper edges and more intricate part designs compared to other molding methods. It is well-suited for molding around inserts or metal parts, expanding its applicability across industries.

High Cavity Count:

Transfer molding allows for the use of multiple cavities, resulting in a high yield and increased productivity. One preform can fill hundreds of cavities, which is an advantage over compression molding.

Improved Part Quality:

The closed mold and precise control over material distribution lead to greater consistency and quality in the finished parts. Transfer molding often yields parts with a smooth, finished surface, reducing the need for additional finishing steps.

The Disadvantage of Transfer Molding

Higher Tooling and Equipment Costs:

The transfer molding process requires more complex tooling and equipment compared to other molding methods. The mold design and maintenance of the transfer pot and plunger system can be costly.

Longer Setup and Changeover Times:

Transfer molding has a longer cycle time and setup compared to injection molding due to the extra step of transferring material, mold preparation, and machine adjustments.

Material Wastage:

Transfer molding can result in material wastage, such as from the sprue and overflow grooves, which need to be trimmed and discarded. This can lead to higher material expenses.

What are the Materials Used in Transfer Molding?

Epoxy:

Epoxy is a thermosetting polymer known for its excellent electrical insulation properties and high resistance to chemical attack. It has a low viscosity, allowing for precise mold detail replication, but can be brittle and may need post-process curing for optimal strength.

Silicone:

Silicone is renowned for its temperature resistance, durability, flexibility, and biocompatibility. However, silicone is more expensive and has a longer curing time than materials like epoxy.

Polymers and Plastics:

Polyurethane and polyester are used in transfer molding due to their strength, chemical resistance, and flexibility. Polypropylene and polycarbonate are used for their flow properties, chemical resistance, and dimensional stability.

Some plastics, like ABS, may cause issues related to dimensional stability in transfer molding.

Rubber:

Rubber, both natural and synthetic, can be used in transfer molding due to its high elasticity and resilience. Post-curing or vulcanization may be required to obtain the best properties.

The Transfer Molding Applications

Automotive Industry:

Transfer molding is extensively used in the automotive industry for manufacturing a wide range of components, including gaskets, seals, O-rings, bushings, and electrical connectors. These parts require durability, resistance to fluids and temperature variations, and precise dimensional control, all of which can be achieved through transfer molding.

Electronics and Electrical Components:

In the electronics sector, transfer molding is employed to produce encapsulated components such as integrated circuits (ICs), sensors, connectors, and switches. The process provides excellent protection against moisture, dust, and mechanical damage while ensuring electrical insulation and reliability in harsh operating environments.

Aerospace and Aviation:

Transfer molding is used in the aerospace and aviation industries to fabricate critical components like seals, gaskets, insulators, and structural parts. These components must withstand extreme temperatures, high pressures, and rigorous performance requirements, making transfer molding an ideal choice for producing high-strength and lightweight parts with consistent quality.

Consumer Goods and Appliances:

Transfer molding is employed in the manufacturing of various consumer goods and household appliances, including kitchen appliances, power tools, and sporting equipment. The process is used to produce grips, handles, knobs, and other molded parts that require ergonomic designs, durability, and aesthetic appeal.

Medical Devices and Healthcare Products:

Transfer molding is utilized in the medical device industry to produce components for healthcare products such as catheters, syringes, surgical instruments, and implantable devices. The process offers biocompatible materials, precise molding capabilities, and stringent quality control to meet regulatory standards and ensure patient safety.

Industrial Machinery and Equipment:

Transfer molding finds applications in industrial machinery and equipment for manufacturing components like bushings, seals, and vibration dampeners. These parts are essential for ensuring proper functionality, minimizing wear and tear, and enhancing the overall performance and lifespan of machinery and equipment.

Oil and Gas Industry:

In the oil and gas sector, transfer molding is utilized to produce seals, gaskets, and other components used in drilling equipment, pipelines, valves, and offshore platforms. These parts must withstand harsh operating conditions, including high pressures, temperatures, and exposure to corrosive fluids, making transfer molding an ideal choice for their fabrication.

Rubber Transfer Molding Applications

The Comparison of Compression, Transfer, and Injection Molding

This section highlights the key differences between compression, transfer, and injection molding,helping you determine which process best fits your application.

| Feature | Compression Molding | Transfer Molding | Injection Molding |

|---|---|---|---|

| Tooling Cost | Low | Medium | High |

| Cycle Time | Slow | Moderate | Fast |

| Shape Complexity | Simple | Moderate | Complex |

| Flash & Trim | High | Low | Very low |

| Dimensional Control | Good | Better | Best |

Which Molding Method Fits Your Application?

Consider:

- Material type (thermoset vs thermoplastic)

- Part complexity and precision needs

- Flash tolerance and finishing capabilities

- Volume requirements and cost constraints

Need help choosing the best molding method for your project? Contact our experts to evaluate your design, recommended cost-effective tooling strategy, and optimal material selection for your project.

FAQs of Transfer Molding

Is heat resistance a feature of transfer-molded products?

Yes. Transfer molding is ideal for producing heat-resistant parts using materials like silicone rubber and phenolic resins. These materials maintain performance under elevated temperatures, making them suitable for applications.

Can transfer-molded parts be stretchable?

Yes, depending on the material. When using elastomers such as silicone, polyurethane thermosets, or other flexible rubbers, transfer molding can produce components with good stretchability and elasticity.

What is the expected lifespan of transfer-molded components?

Lifespan varies by material and usage conditions. However, properly engineered transfer-molded parts typically last 5 to 20+ years, especially when made from durable thermosets or high-performance rubbers.

What does “cull” mean in transfer molding?

“Cull” refers to the cured residual material left in the transfer pot after the molding cycle. This waste is a normal byproduct of the process and must be removed after each cycle.