What is Rubber Compression Molding?

Custom Rubber moulding methods like compression molding involve placing a pre-measured rubber compound—often in the form of a preform or charge—is placed into a heated mold cavity, and then the mold is closed and pressurized. As one of the common types of rubber molding, the compound cures (vulcanizes) under heat and pressure to take the cavity’s shape. This process is particularly efficient for low-to medium-volume runs and large or thick rubber parts.

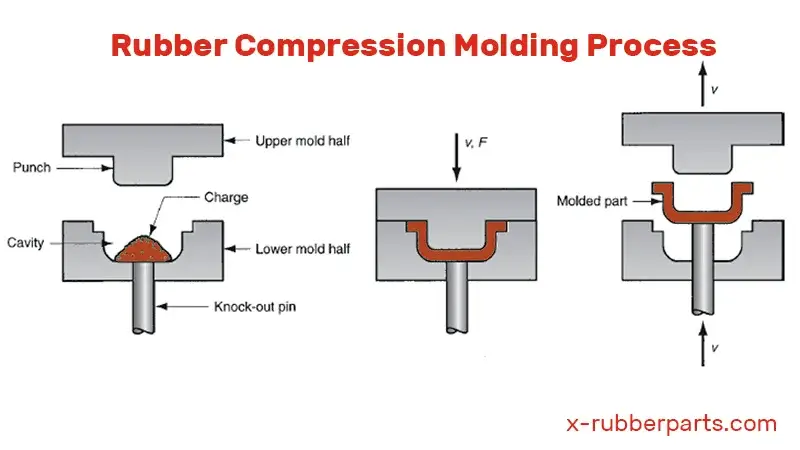

Rubber Compression Molding Process

1.Material Preparation (Compound) – mixing and preparing rubber formula

2.Preforming – cutting or pressing compound into precise shape/weight

3.Mold Loading – placing preform in the mold cavity

4.Mold Closing & Heating – closing mold and applying pressure and heat

5.Curing/Crosslinking – holding temperature & pressure to vulcanize

6.Cooling & Demolding – opening mold and removing part

7.Post-processing – trimming, deburring, inspection

Mold Types & Key Design Considerations

1. Flash Type Mold

This mold type involves slightly overfilling the cavity with rubber compound, allowing excess material to escape along the horizontal parting line as “flash” when the mold closes. It is ideal for flat or shallow parts due to its lower tooling cost and simple operation, and is especially suitable when inserting metal or fabric components. Flash molds are also less likely to produce internal blisters. However, mold closing speed must be carefully controlled—closing too slowly increases flash, while closing too quickly can reduce part density and strength.

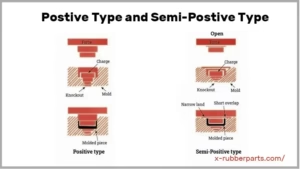

2. Positive Type Mold

A positive mold is designed for precision by using a pre-measured rubber compound that fully fills the mold cavity without excess material. This method ensures excellent control over part density, minimizes material waste, and is ideal for high-performance applications that use expensive or specialty thermoset rubber compounds. However, this approach requires accurate preforming, high tooling costs, and strict process control to ensure consistent results.

3. Semi-Positive Mold

The semi-positive mold offers a balanced approach by combining the controlled material use of a positive mold with limited flash allowance. It provides better quality parts for complex geometries, is more forgiving with preform size, and benefits from the strengths of both flash and positive mold types. That said, it typically comes with the highest tooling costs and is often reserved for precision or intricately shaped components.

Key Design Considerations

Weight: Reduce mold weight to save energy and improve production speed, without compromising strength.

Flexibility: Use interchangeable inserts or adjustable cavities to accommodate various part shapes.

Vibration Dampening: Add shock absorbers or dampening materials to minimize defects caused by machine vibration.

Mechanical Properties: Design molds to withstand the rubber’s strength, elasticity, and hardness for consistent quality.

Cost Optimization: Balance performance and cost with simplified structures and affordable materials.

Pressure Requirements: Ensure the mold can apply adequate pressure for complete filling and proper curing.

Thermal Decoupling: Use insulation or cooling channels to manage heat and prevent curing defects.

Advantages of Rubber Compression Molding

- Low tooling cost vs injection molding

- Ideal for thick or large parts

- Minimal material waste—trim flash can be recycled

- Broad material compatibility (silicone, NR, EPDM, etc.)

- Simple process for prototyping and small batches

- Low-maintenance mold fixtures

Disadvantages (Limitations & Solutions)

- Slower cycle times → Fix: utilize multi-cavity molds or semi-automated presses

- Lower dimensional precision → Fix: high-precision closed molds, CNC machined tooling

- Flash buildup → Fix: optimize mold fit, reduce charge weight, improve venting

- Incomplete fills / short-shots → Fix: increase temperature/pressure, redesign flow paths

- Voids or blisters → Fix: provide adequate venting and adjust cure time/temperature

Materials for Rubber Compression Molding

Natural Rubber (NR)

Nitrile Rubber (NBR)

Ethylene Propylene Diene Monomer (EPDM)

Silicone Rubber (VMQ)

Fluoroelastomer (FKM)

Styrene-Butadiene Rubber (SBR)

Chloroprene Rubber (CR)

Isobutylene Isoprene Rubber (IIR)

Compression Molding Application

Compression molded components are widely used across various industries.

Automotive Industry: Compression molding is found to be extensively used in the automotive sector to manufacture gaskets, seals, engine components, and interior trim pieces.

Electrical Industry: Compression molding is essential for producing circuit breakers, connectors, and insulators, integral components of electrical systems.

Consumer Goods: Everyday items like bakelite handles for cookware, gaming pieces, and buttons often rely on compression molding for their production.

Construction Industry: Vibration dampeners and structural components used in construction applications are produced using compression molding.

Sporting Goods: Golf balls and various equipment components in the sporting goods industry are manufactured using compression molding.

Choosing the Right Rubber Compression Molding Manufacturer

Selecting the right rubber compression molding manufacturer is critical to your product’s success. From in-house mold design and quality control to technical support and certified production standards, a reliable partner should support everything from prototyping to volume manufacturing with competitive pricing and fast lead times.