Polypropylene is a thermoplastic polymer made from propylene monomers through polymerization. It has a density between 0.895 and 0.92 grams per cubic centimeter, making it one of the lighter plastics.

What is The Types of Polypropylene?

Polypropylene is available in two main types: homopolymer and copolymer.

Homopolymer polypropylene consists of a single type of monomer, providing higher strength and rigidity. It has good heat resistance but can be brittle at low temperatures.

Copolymer polypropylene incorporates ethylene or other monomers, improving impact resistance and flexibility. Random copolymers offer better clarity, while block copolymers enhance toughness. These variations allow selection based on specific requirements in pp injection molding.

Importance of Using Polypropylene for Injection Molding

Using polypropylene in injection molding provides multiple benefits related to material properties and process efficiency.

- PP has a low melt viscosity, which enables it to flow easily into intricate mold designs during pp plastic injection molding. This characteristic shortens cycle times, typically to 15-30 seconds per part, increasing throughput in production lines.

- The low cost of polypropylene raw material, often less than other engineering plastics, makes injection moulding pp economically viable for large-scale operations.

- Polypropylene offers good chemical resistance to non-oxidizing acids, alkalis, and many organic solvents, making it suitable for containers and pipes in chemical environments.

- Its low moisture absorption rate, under 0.01 percent, eliminates the need for pre-drying in most cases, simplifying the polypropylene injection molding process.

- PP provides electrical insulation with a dielectric constant around 2.2-2.6, useful for electronic housings produced via pp injection moulding.

- Polypropylene is also lightweight, reducing transportation costs and improving fuel

Disadvantages of Polypropylene Injection Molding

Despite its benefits, polypropylene injection molding has limitations.

- PP has a high thermal expansion coefficient, leading to dimensional changes with temperature variations. This can cause warping in parts exposed to heat above 80 degrees Celsius.

- The material is sensitive to ultraviolet radiation, which causes degradation and loss of mechanical properties over time without additives.

- The material has poor adhesion to coatings and adhesives without plasma or flame treatment, complicating secondary operations in pp injection.

- In polypropylene plastic injection molding, shrinkage rates of 1 to 3 percent must be accounted for to maintain accuracy.

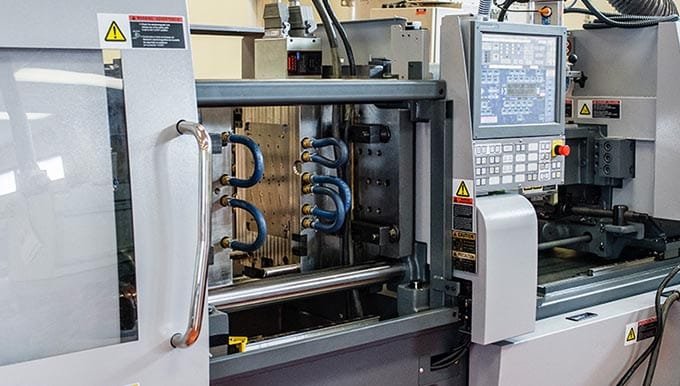

Polypropylene Injection Molding Process Steps

The injection molding polypropylene process involves several sequential steps to transform raw material into finished parts.

- Melting and Plasticization: Polypropylene pellets are loaded into a hopper connected to the injection machine. The pellets are gravity-fed into a heated barrel where a screw rotates to melt them. Temperatures range from 220 to 280 degrees Celsius to achieve proper melt consistency without degradation.

- Injection: Once molten, the screw advances to inject the material into the mold cavity under pressures of 5.5 to 10 megapascals. This step fills the mold quickly to prevent defects.

- Holding Pressure: After injection, a holding pressure is applied to compensate for material shrinkage as it cools. Mold temperatures are maintained between 20 and 80 degrees Celsius, typically around 50 degrees Celsius, to control cooling rates.

- Cooling and Solidification: Cooling time varies based on part thickness but usually lasts seconds to minutes.

- Ejection: When the part solidifies, the mold opens, and ejector pins remove the component. The cycle repeats for continuous production.

Plastic Molding Solutions

Design Guidelines for Polypropylene Injection Molding

Wall Thickness and Uniformity

Wall thickness should range between 1.5 and 3.5 millimeters to promote uniform cooling in pp plastic injection molding. Consistent thickness prevents sink marks and internal stresses.

Draft Angles and Ejection

Draft angles of 1 to 2 degrees per side are necessary for smooth part ejection from the mold in injection moulding pp. For surfaces with textures, increase the angle to 5 degrees to prevent sticking.

Corner Radii and Stress Distribution

Corners should have radii at least 25 percent of the wall thickness, ideally 75 percent, to minimize stress concentrations in injection polypropylene.

Ribs and Structural Reinforcement

Ribs should have a thickness no greater than 50 percent of the adjacent wall and a height not exceeding 2-3 times the base width. This design in polypropylene plastic injection molding prevents sink marks on the opposite surface while adding strength without excessive material use.

Bosses and Fastener Support

Bosses for screws or inserts require sufficient wall thickness around them, typically 2.5 times the screw diameter. Adding fillets at the base of bosses in pp injection moulding enhances strength and reduces stress risers, ensuring reliable fastening points.

Gate Placement and Flow Optimization

Gates should be placed at the thickest section of the part to ensure complete mold filling before thinner areas solidify in the polypropylene injection molding process. Pin gates with diameters of 0.7 to 1.5 millimeters are common for precise control, minimizing residual stresses in pp injection.

Venting and Air Escape

Proper size and location vents are important to allow trapped air to escape, preventing burn marks or voids in injection molding polypropylene plastic.

Applications of Polypropylene Injection Molding

Injection molding polypropylene plastic is widely used in various sectors:

- Packaging: Food containers, yogurt cups, and other consumer goods packaging.

- Automotive: Interior trims, battery cases, and living hinges.

- Medical: Disposable instruments and medical device components.

- Textiles: Components for synthetic fibers.

- Consumer Goods: Toys, household items, and appliances.

Zhongren Professional Custom Polypropylene Injection Molding Services

Polypropylene injection molding combines material advantages with efficient processing for various products. Zhongren provides custom services for plastic molding, including mold fabrication, prototyping, and volume production. For inquiries on pp injection molding projects, contact Zhongren to discuss specific needs.