Polycarbonate molding, especially polycarbonate injection molding, is the most common process in manufacturing versatile, high-performance plastic parts. This guide delves deep into the polycarbonate molding process, its techniques, advantages, challenges, and design considerations.

What is Polycarbonate Material?

Molded polycarbonate is a high-performance amorphous thermoplastic. It is synthesized from bisphenol A and phosgene, delivering a unique blend of optical purity and mechanical resilience. With a density of 1.2-1.22 g/cm³ and a shrinkage rate of 0.4-0.7%, it boasts 80-90% light transmission and a haze below 1%. Its tensile strength (55-75 MPa) and elongation at break (80-150%) shine from -40°C to 120°C.

Polycarbonate plastic molding excels in chemical resistance and electrical insulation but is prone to UV degradation and moisture absorption, requiring stabilizers or pre-drying.

Benefits of Polycarbonate Injection Molding

The popularity of polycarbonate injection molding lies not just in the material but in the process’s ability to transform it into high-performance parts with finesse. Here are the key advantages:

- Efficiency and speed: The process is automated, delivering faster production cycles and reduced labor costs, enabling rapid high-volume manufacturing.

- Complex Geometry Capability: PC injection molding supports intricate mold designs to produce detailed, complex geometry components.

- High precision and consistency: The polycarbonate plastic injection molding process maintains tight tolerances, ensuring uniformity across large batches.

- Cost-effectiveness at scale: Although initial mold costs are high, the per-part cost drops significantly as production volume increases, making it ideal for mass production.

- Versatile Processing Options: The PC injection process accommodates advanced techniques like overmolding and thin-wall molding, enhancing functionality for hybrid parts.

- Low Waste and Recyclability: The polycarbonate plastic molding process minimizes material waste and supports recycling of regrind, aligning with sustainable manufacturing practices.

- Accommodates a wide range of part sizes: Polycarbonate injection molding is versatile in producing small to large components.

Disadvantages and Challenges of Polycarbonate Injection Molding

Despite its benefits, polycarbonate injection molding presents notable challenges. The high initial cost of tooling and machinery can be prohibitive for low-volume production runs, making PC injection molding less economical for small batches. Polycarbonate’s high melt viscosity requires meticulous temperature and pressure control to prevent degradation of the material. Additionally, PC molding demands thorough drying of the pellets to prevent moisture-related defects such as splaying or surface blemishes. These technical hurdles necessitate skilled process management to maintain quality and yield.

Polycarbonate Injection Molding Technologies

Polycarbonate molding leverages advanced techniques to meet diverse needs. Each method enhances specific outcomes:

- Rapid Heat and Cool (RH&C): This technique preheats molds and then rapidly cools them to eliminate weld lines. It is ideal for producing flawless optical lenses.

- Water-Assisted Injection: High-pressure water forms hollow cores, ensuring uniform thin walls. It is perfect for large tubing, as it reduces weight.

- Overmolding: Secondary injection bonds PC to other materials, like TPU, for hybrid parts. It is used in ergonomic electronic casings.

- Thin-Wall Molding: High-shear injection fills slim structures, cutting material use. It is common in phone casings, speeding cycles by 20%.

- Structural Foam Molding: Foaming agents create lightweight cores for large parts. Aerospace panels benefit, saving 15% in costs.

The Polycarbonate Injection Molding Process

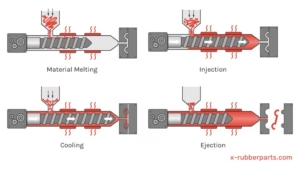

The polycarbonate injection molding process generally comprises several stages:

- Material Preparation: Raw polycarbonate pellets are dried thoroughly to remove moisture.

- Feeding and Melting: Pellets are fed into the injection molding machine’s heated barrel and melted under controlled temperature and pressure.

- Injection: The molten polycarbonate is injected into the mold cavity at high pressure, filling the mold precisely.

- Cooling: The molded polycarbonate cools within the mold, solidifying into the desired shape.

- Ejection: The finished polycarbonate part is ejected from the mold.

- Post-Processing: Additional steps such as trimming, surface finishing, or assembly may follow.

Design Guidelines for Polycarbonate Injection Molding

Effective polycarbonate plastic injection molding hinges on mold design precision. Key considerations include:

Wall Thickness: Keep uniform at 1-3.8 mm; minimum 1 mm for thin walls to avoid underfill. Scale molds 0.5% to account for shrinkage.

Draft Angle: Apply 0.5-1° on sidewalls, 3° for textured surfaces, ensuring smooth ejection without scratches.

Gate Placement: Position gates in thicker areas to avoid weld lines. Use edge or fan gates for even flow distribution.

Cooling System: Design uniform channels, keeping temperature variance <10°C to prevent warpage and optimize cycle time.

Fillet Radius: Use R>3 mm to minimize stress concentrations; polish molds for glossy finishes.

Rib Structure: Limit height to <3x wall thickness, thickness at 0.5-0.6x wall to distribute loads.

Venting: Incorporate 0.01-0.03 mm vents at flow ends to prevent air traps.

Surface Treatment: Chrome-plate molds to reduce sticking; matte finishes reduce glare for optics.

Processing Guidelines for Polycarbonate Molding

Precise parameters are critical for PC injection molding. Below are key settings and their impacts:

| Parameter | Recommended Value | Impact and Adjustments |

|---|---|---|

| Melt Temperature | 220-300°C | Low causes viscosity; high risks degradation. Adjust per MFR. |

| Mold Temperature | 70-100°C | Low risks warpage; high enhances clarity. Use uniform channels. |

| Injection Pressure | 70-140 MPa | High fills thin walls; avoid overpressure to prevent flash. |

| Holding Pressure | 50-80% of injection | Compensates shrinkage, reduces sink marks. Gradually increase. |

| Injection Speed | 50-200 mm/s | Fast for complex shapes; slow to avoid jetting. |

| Screw Speed | 50-200 RPM | Ensures uniform melt; high speeds risk air entrapment. |

Common Issues in Polycarbonate Molding and Solutions

Polycarbonate injection can face defects, but solutions exist:

- Flow Lines: Uneven melt flow causes streaks. Increase speed, pressure, or temperature for uniform filling.

- Flash: Resin leaks from mold seams. Boost clamping force, check mold alignment, and adjust temperature/speed.

- Sink Marks: Uneven cooling creates depressions. Lower mold temperature, increase holding pressure, or design uniform walls.

- Weld Lines: Weld lines are weak seams where melt fronts meet during injection molding. To minimized weld lines, raise temperature/speed, position gates near thick areas, or redesign flow paths.

- Jetting: Jetting appears as wrinkled surfaces caused by rapid injection. Ensure mold wall contact, adjust melt temperature/speed, and optimize viscosity to prevent jetting.

- Warpage: Non-uniform cooling distorts parts. Optimize cooling channels or apply post-molding annealing.

- Voids: Trapped air forms cavities. Place gates in thick zones, use low-viscosity grades, and enhance venting.

- Burn Marks: Overheating causes charring. Reduce screw speed, improve ventilation, or shorten residence time.

Applications of Polycarbonate Injection Molding

Polycarbonate molded parts serve diverse industries:

- Automotive: Headlights, dashboards, and interiors.

- Consumer Electronics: Device housings and optical components.

- Medical Devices: Sterilizable components requiring impact resistance.

- Protective Gear: Helmet visors, goggles.

Zhongren’s Expertise in Polycarbonate Injection Molding

Zhongren specializes in custom plastic moulding service, leveraging cutting-edge equipment and expertise to deliver high-quality molded polycarbonate parts tailored to specific needs. With comprehensive quality control and process optimization, Zhongren ensures efficient production, cost-effectiveness, and reliable delivery.