Plastic molding toys, crafted through the precise process of injection molding, bring vibrant, durable playthings to life. This guide explains how Zhongren uses advanced injection molding technology to produce high-quality toys, focusing on the process, advantages, material selection, and its applications.

What is Injection Molding Toys?

Injection molding toys is a common process for manufacturing toys. The process involves injecting molten plastic into precisely crafted molds to create detailed plastic toys. This process enables the mass production of durable, high-quality plastic toys with intricate details and consistent shapes.

Injection Molding Toys Operation Process

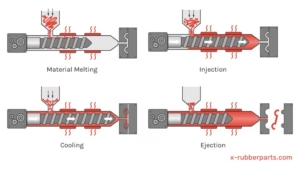

Injection molding toy production follows an efficient, precision-driven process designed for consistent quality. Here’s how it works:

- Mold Design: Engineers craft a mold, typically made of steel or aluminum, tailored to the toy’s specifications.

- Material Melting: Plastic pellets, such as ABS or polypropylene, are heated until they become molten.

- Injection: The molten plastic is injected into the mold under high pressure, known as clamping force, ensuring every detail is captured.

- Cooling: The plastic cools and solidifies within the mold, forming the toy’s shape.

- Ejection: The mold opens, and the finished plastic molding toy is ejected, ready for finishing touches like painting or assembly.

Advantages and Disadvantages of Injection Molding Toys

Advantages of Injeciton Molding Toys

The production of injection molding toys offers numerous benefits, making it a preferred method in the toy industry:

High Production Efficiency: Once the mold is created, thousands to millions of identical parts can be produced rapidly, enabling mass production at a low per-unit cost.

Dimensional Accuracy and Detail: Injection molding allows for complex designs with fine details, sharp edges, and consistent dimensions that are difficult to achieve by hand or other molding methods.

Material Versatility: A wide range of engineering and commodity plastics can be selected to achieve specific mechanical properties, durability, and safety requirements tailored to different toy functions.

Consistent Quality: Automated processes ensure every plastic molding toy meets identical standards.

Customization and Color Control: Multiple colors can be injected simultaneously (multi-shot molding), and post-processing options like painting or decals enhance toy aesthetics.

Disadvantages of Injection Molding Toys

Despite its strengths, injection molding toys come with several challenges:

High Initial Costs: Designing and manufacturing precision molds requires significant upfront investment, which may not be economical for low-volume production.

Long Setup Time: Mold fabrication, testing, and adjustments can extend project timelines, delaying the initial time to market.

Material Limitations: Not all plastics are suitable for injection molding; materials must withstand high processing temperatures and pressures.

Limited Design Flexibility: Once molds are made, design changes become costly and time-consuming, reducing flexibility for late-stage modifications.

Size and Complexity Constraints: Very large or highly intricate parts may be technically challenging or costly to produce due to mold design and machine capacity limits.

Environmental Impact: While many plastics are recyclable, the process still consumes significant energy and typically relies on petroleum-based materials, raising sustainability concerns.

Common Materials for Toys and Selection Considerations

Selecting the right materials for plastic molding toys is critical to ensure safety, durability, and environmental responsibility. Below are the most common materials and key considerations for their selection:

Common Materials

- Acrylonitrile Butadiene Styrene (ABS): Known for its strength, rigidity, and lightweight properties, ABS is ideal for injection molding toys like action figures and building blocks.

- Polypropylene (PP): This versatile, tough plastic offers flexibility and resilience, making it suitable for injection moulding toys like soft, squeezable toys or components that need to withstand rough play. PP is also cost-effective and easily tinted for vibrant colors.

- Polyethylene (PE): Lightweight and weather-resistant, PE is often used for outdoor plastic molding toys like playground equipment or water toys due to its durability and non-slip properties.

- Polyvinyl Chloride (PVC): Offering a wide range of textures from soft to rigid, PVC is used in injection molded toys such as dolls, toy vehicles, and inflatable toys.

- Thermoplastic Elastomers (TPE): Combining rubber-like elasticity with plastic moldability, TPE is perfect for soft, tactile injection molding toys like teething rings or flexible figurines.

Selection Considerations

- Child Safety: All materials must be non-toxic and comply with stringent regulations like ASTM F963 or EN71 to ensure injection moulding toys are safe for children.

- Durability vs. Cost: Balance material strength with production budgets. For example, ABS offers durability for high-end toys, while PP provides a cost-effective alternative for mass-market products.

- Environmental Impact: Prioritize recyclable plastics like PP or PE to align with eco-conscious trends, reducing the environmental footprint of plastic molding toys.

- Functional Fit: Match material properties to the toy’s purpose—rigid ABS for structural toys, flexible TPE for soft, squeezable designs, or transparent polystyrene for aesthetic components.

Common Mold Materials and Design Considerations

Injection molding relies on durable, precisely engineered molds:

Mold Materials

- Steel: Offers superior durability for high-volume toy production.

- Aluminum: Lightweight and cost-effective, suitable for smaller runs and prototyping.

Key Design Considerations

- Maintain tight tolerances for detailed toy parts.

- Integrate efficient cooling channels to reduce cycle times and defects.

- Apply draft angles to aid smooth part ejection.

- Balance design complexity with mold cost to stay within budget.

Products Made by Injection Molding Toys

The versatility of injection moulding toys shines through in the vast array of products they create. Common examples include:

Action Figures and Dolls: Highly detailed characters made with multiple components including accessories.

Building Blocks: Interlocking bricks, like LEGO-style sets, rely on the precision of plastic molding toys to ensure perfect fits and endless creative possibilities.

Toy Vehicles: Cars, trains, and planes with moving parts are crafted as injection molding toys, combining durability with detailed designs.

Outdoor and Sports Toys: Lightweight and sturdy balls, flying discs, and other recreational items.

Puzzles and Board Game Pieces: Intricate shapes, from jigsaw pieces to game tokens, showcase the precision of injection moulding toys.

Bath and Pool Toys: Water-safe, durable toys designed for aquatic environments.

Educational Toys: Shape sorters, stackers, and alphabet blocks, produced as plastic molding toys.

Sustainable Practices in Injection Molding Toys

Sustainability is a growing concern in the toy industry. Using recycled plastics and biodegradable materials like PLA to minimize waste and reliance on virgin petroleum-based resins. Implementing optimized molding cycles to reduce energy consumption. Designing for disassembly, allowing toys to be easily recycled at end-of-life. Minimizing packaging waste by adopting eco-friendly designs. These practices address consumer demand for greener products and align with global efforts to promote circular economies.

Partner with Zhongren

If you’re looking for a trusted partner to produce durable, high-quality injection-molded toys, Zhongren is here to help. Our expertise, advanced technology, and commitment to quality ensure your products meet global standards and market demands.

Contact us today to discover how our toy injection molding solutions can bring your ideas to life.