Injection molding is a common technology used to produce various parts and components for different applications. However, the costs involved can vary greatly depending on factors like mold complexity, material choice, and production volume. Understanding these cost factors is essential to determining if this process fits your manufacturing needs. This guide explores the main elements affecting injection molding costs and offers strategies to reduce expenses without sacrificing product quality.

How to Calculate Injection Molding Pricing?

Calculating injection molding cost involves summing fixed and variable components, with a focus on amortizing high initial expenses over production volume. A basic formula for total injection molding price is:

Total Cost = Tooling Cost + (Material Cost per Part + Labor Cost per Part + Machine Operation Cost per Part) × Number of Parts + Secondary Services Cost

Here, the injection mold tooling cost is the initial investment in creating the mold, which can vary widely based on design complexity and material. Material cost per part depends on the type of injection molding materials used, and labor cost plus machine operation cost adjusted for automation.

Types of Costs in Injection Molding

Injection Mold Cost

Beyond the initial tooling investment, an injection mold affects hidden production costs, including cooling inefficiency, poor tolerances, longer cycles, and higher rejection rates. The mold’s manufacturing cost increases when the product is more complex or when more durable materials are chosen for the mold, as both require more machining time and precision.

- CNC Machining: CNC machining is the core process in mold manufacturing. Its cost is driven mainly by two factors — the hardness of the mold material and the complexity of the mold structure. Harder materials like H13 or S136 steel take more time to cut and wear tools faster, directly raising machining hours and tool replacement cost. Complex molds with multiple cavities, deep cores, or tight tolerances also add to programming and setup time. A precise mold reduces fitting, spotting, and later adjustment work, which often saves more time and money during molding production than the initial machining cost itself.

- Electrical Discharge Machining (EDM): EDM is used when the mold requires fine details, deep ribs, or sharp internal corners that cannot be achieved by conventional cutting. It is a slower process and needs custom electrodes, so the upfront cost is higher.

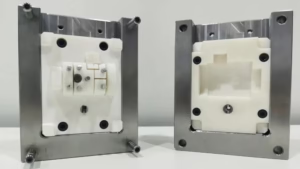

- 3D Printing: Unlike traditional CNC tooling, it requires minimal equipment and less specialized labor, freeing up skilled operators for higher-value tasks. Manufacturers can leverage in-house 3D printing to produce molds suitable for both desktop and industrial injection molding machines, allowing faster design iteration and testing with end-use materials before committing to expensive hard tooling.

Equipment Cost

Injection molding machines range from small desktop units for prototyping to large industrial presses. Machine size, complexity, and automation affect both upfront and production costs.

Desktop machines with 3D-printed molds are cost-effective for small batches, while industrial machines ($50,000–$200,000+) require skilled operators and high maintenance. Hydraulic presses are durable and affordable but less precise; electric presses are accurate and energy-efficient but cost more; hybrid machines combine both. For most companies, custom plastic molding through outsourcing is the simplest way to avoid high equipment and operational costs while maintaining quality consistency.

Plastic Resins and Additives Cost

Plastic resins range from $2 to $90 per pound, with engineering plastics like PC and POM being more expensive. In addition to resins, additives such as heat stabilizers or plasticizers can affect cost. Selection depends on part application, chemical resistance, appearance, regulatory requirements, and expected lifespan. Resins are supplied as pellets, and bulk purchases often offer discounts. Common materials include PC, ABS, PU, PP, and PE, with final cost depending on usage, additives, and design complexity.

Factors Affecting Injection Molded Part Costs

Design Complexity

Parts with intricate geometries, deep features, or tight tolerances require more sophisticated mold-making techniques, such as EDM, CNC, or 3D-printed inserts. These designs often consume more material and may slow production cycles, both of which increase costs.

Material Volume

The overall size and thickness of a part directly affect the amount of plastic used. Larger, thicker components require more resin, longer injection times, and potentially bigger machines, which cumulatively raise production expenses.

Functional Features

Features such as undercuts, threads, or internal cavities add complexity to mold design. While sometimes necessary, these elements often require sliding cores or additional mold components, driving up tooling and cycle costs.

Surface and Cosmetic Requirements

High-quality finishes, textures, or color matching can increase mold and processing demands. Each added cosmetic feature may require extra mold cavities or longer cycle times.

Part Consistency and Tolerance

Parts that require tight dimensional tolerances or consistent mechanical performance may necessitate stricter quality control and specialized processing parameters, which can increase labor, inspection, and scrap rates.

Labor and Service Costs

Even with highly automated injection molding processes, labor remains a significant factor in production costs. Skilled personnel are required to set up and calibrate machines, ensure molds are properly installed, and monitor operations to maintain consistent quality.

Routine maintenance, troubleshooting, and adjustments also rely on trained staff, adding to overall expenses. For outsourced projects, service providers include labor, supervision, and overhead in their quoted fees, ensuring the finished parts meet quality and delivery expectations. Some projects may also require overmolding or rubber bonding service, which integrates rubber with plastic or metal parts for enhanced durability and performance.

Injection Molding Cost Across Production Volumes

Injection molding cost varies significantly with production volume, as fixed tooling expenses are spread over more units in larger runs. Below is a table for the cost associated with injection molding a hypothetical plastic item, which makes the cost dynamics of injection molding easier to understand:

| Metric | Small Batch (100-1,000 parts) | Medium Batch (5,000-10,000 parts) | Large Batch (100,000+ parts) |

|---|---|---|---|

| Production Volume | 100-1,000 | 5,000-10,000 | 100,000+ |

| Method | In-house mold production and molding | Outsourced mold production and molding | Outsourced mold production and molding |

| Mold Type/Material | 3D-Printed Polymer/Aluminum | Machined Aluminum/Pre-Hardened Steel | Machined Hardened Steel |

| Lead Time to Final Parts | 1-3 days | 3-4 weeks | 4-8 weeks |

| Tooling Cost | $100-$1,000 | $2,500-$5,000 | $20,000-$75,000 |

| Material Cost per Part | $0.50 | $0.50 | $0.50 |

| Labor Cost per Part | $2.50-$3.00 | $1.50-$2.00 | $1.00 |

| Total Run Cost | $450-$4,500 | $15,000-$30,000 | $170,000-$525,000 |

| Cost per Part | $4.00-$4.50 | $2.60-$3.00 | $1.70-$1.75 |

How to Reduce Injection Molding Costs?

Reducing injection molding cost can lower production expenses by 20–40% while maintaining part quality, if approached strategically. It’s important to identify which areas to optimize and which savings could create problems down the line.

1. Optimize Part Design Early

- Apply DFM (Design for Manufacturing) Analysis: Review CAD models early to identify steep angles, undercuts, or wall thickness variations. Uniform 1–2mm walls and 1–2° drafts reduce mold complexity, simplify ejection, and shorten fabrication time.

- Simplify Geometry: Remove non-essential features or cosmetic details that don’t impact function. Skip glossy finishes unless market value justifies them. Simplification shrinks mold size, shortens cycle time, and lowers energy and labor costs.

2. Reduce Mold Costs

- Use Core-Cavity and Self-Mating Designs: For symmetrical or rotatable parts, these designs allow fewer mold components, reducing fabrication and maintenance costs.

- Choose Standard or Reusable Molds: Standard molds can be used across multiple runs, reaching 50,000–1,000,000 cycles with proper maintenance, lowering per-part cost.

- Buy Spare Components: Investing upfront in replacement inserts or pins prevents downtime and costly emergency repairs.

3. Optimize Material Usage

- Select Cost-Effective Resins: Materials like ABS or PP often meet performance needs at lower cost. High-performance resins should only be used when required.

- Recycle Waste Wisely: Reuse sprue and runner material where possible, but limit recycling cycles to avoid degradation of mechanical properties (e.g., tensile strength can drop up to 40% after multiple cycles).

4. Improve Production Efficiency

- Insert Molding: Integrating threads or components during molding reduces assembly time and labor.

- Scale Production Strategically: Higher volumes amortize tooling and equipment costs, but only after careful demand analysis to avoid excess inventory.

- Monitor and Maintain Equipment: Proactive maintenance and process control prevent downtime and defective parts, lowering total cost per part.

By approaching cost reduction strategically, focusing on design, mold, materials, and production, manufacturers can achieve meaningful savings without sacrificing quality or increasing long-term risk.

Zhongren is Assisting Customers in Reducing Injection Molding Costs

Zhongren provides specialized injection molding services to help customers manage injection molding costs. The company offers professional mold design and DFM support, reviewing CAD files to simplify geometries and reduce defects, achieving savings in tooling. In materials, Zhongren advises on selections like efficient resins and additives, paired with process optimizations. Efficient production and quality controls, including real-time monitoring and ISO-certified inspections, ensure minimal waste and consistent output, lowering labor costs. Zhongren helps balance plastic injection molding price with quality, supporting projects from small batch to high-volume runs.