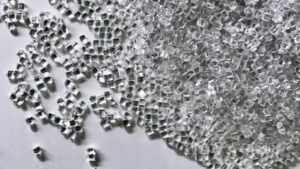

Customized injection molding is a cost-effective, scalable process for producing precise components in large volumes. At the heart of this process are plastic injection molding materials, which determine performance and durability. Understanding plastic molding material properties helps achieve consistent quality and manufacturing success.

Before Selecting Plastic Injection Molding Materials

1. Environmental Impact

Choose biodegradable (e.g., PLA) or recycled materials to reduce your environmental footprint and support sustainable manufacturing practices.

2.Cost&Availability

Balance performance with budget. Some high-performance materials may be expensive or difficult to source—select based on your project’s priorities.

3. Regulatory Compliance

Ensure the material meets industry-specific standards, especially for food contact, medical use, or children’s products. Compliance reduces legal and safety risks.

4. Post-Processing Compatibility

Planning to paint, plate, or surface-finish your parts? Pick materials that accommodate your post-processing requirements for optimal appearance and performance.

5. Application-Specific Properties

Consider key properties like strength, heat resistance, tensile strength, and Heat Deflection Temperature (HDT) to ensure the material performs reliably in real-world conditions.

Common Plastic Injection Molding Materials

1.Acrylonitrile Butadiene Styrene (ABS)

Material Characteristics: ABS offers high strength and excellent dimensional stability, making it a reliable material for precision parts. Its good impact resistance and compatibility with post-processing techniques like painting and plating make it highly versatile.

Typical Applications: Automotive parts, electrical enclosures, toys, and home appliances.

2. Polypropylene (PP)

Material Characteristics: Polypropylene is lightweight and cost-effective, with excellent chemical and moisture resistance. It provides good stiffness and impact strength, making it ideal for products requiring durability without added weight.

Typical Applications: Automotive components (bumpers, battery casings), packaging, consumer goods, and medical devices.

3. Polycarbonate (PC)

Material Characteristics: Known for its transparency and toughness, polycarbonate is impact-resistant, flame-retardant, and can withstand repeated sterilization without degrading, making it suitable for both industrial and medical applications.

Typical Applications: Automotive lenses, safety helmets, electrical components, and medical devices.

4. Nylon (Polyamide, PA6/PA66)

Material Characteristics: Nylon is strong, wear-resistant, and chemically stable, with low friction and excellent thermal resistance. PA66 offers higher rigidity and a higher melting point, while PA6 is softer, easier to dye, and better suited for applications needing flexibility and wear resistance.

Typical Applications: Gears, bearings, connectors, and structural automotive parts.

5.Polyethylene (PE: HDPE & LDPE)

Material Characteristics: Polyethylene is a durable, lightweight, and chemically resistant plastic. HDPE is stiff and strong, ideal for structural components, while LDPE is softer and more flexible, often used in squeezable and flexible packaging.

Typical Applications: HDPE – pipes, containers, fittings. LDPE – squeeze bottles, plastic bags, food wraps.

6. Polyoxymethylene (POM)

Material Characteristics: POM, also known as acetal, features high rigidity, excellent dimensional stability, and low friction. It is self-lubricating and highly resistant to wear and chemicals, making it ideal for mechanical precision parts.

Typical Applications: Gears, bearings, mechanical parts, and automotive fuel system components.

7. Polyethylene Terephthalate (PET)

Material Characteristics: PET is a clear, strong, and heat-resistant material with excellent barrier properties against gases and moisture. It maintains product freshness and is widely used in food and beverage packaging.

Typical Applications: Beverage bottles, food containers, and general-purpose packaging.

8. Polyethylene Terephthalate Glycol (PETG)

Material Characteristics: PETG is transparent, tough, and flexible. It is easy to process and resistant to impact, sterilization, and chemicals, making it ideal for both cosmetic and medical-grade applications.

Typical Applications: Medical devices, cosmetic packaging, signage, and food containers.

9. Polystyrene (PS: GPPS & HIPS)

Material Characteristics: Polystyrene is a lightweight and cost-effective plastic that is easy to mold and print. GPPS offers high clarity for visual applications, while HIPS provides better impact resistance for more durable consumer products.

Typical Applications: Disposable cutlery, cosmetic packaging, toys, and consumer electronics.

10. Polymethyl Methacrylate (PMMA / Acrylic)

Material Characteristics: PMMA provides excellent optical clarity, UV resistance, and surface hardness. Although it is more brittle than polycarbonate, it offers superior scratch resistance, making it a preferred choice for transparent and display parts.

Typical Applications: Light covers, lenses, display panels, and transparent enclosures.

11. Polyphenylene Sulfide (PPS)

Material Characteristics: PPS is known for its high thermal and chemical resistance, flame retardancy, and dimensional stability under mechanical stress. It performs reliably in extreme environments, particularly in electrical and automotive applications.

Typical Applications: Electrical connectors, pump housings, filter components, and automotive parts in high-heat environments.

12. Polyether Ether Ketone (PEEK)

Material Characteristics: PEEK is a high-performance thermoplastic offering exceptional thermal stability, chemical resistance, and mechanical strength. It emits low smoke and toxic gases, making it suitable for demanding industries.

Typical Applications: Aerospace, oil & gas, automotive, and surgical instruments (bearings, seals, connectors, pumps).

13. Polypropylene-Based TPE (Thermoplastic Elastomers)

Material Characteristics: TPEs combine the flexibility and elasticity of rubber with the ease of processing typical of plastics. They are recyclable, impact-resistant, and chemically stable, providing excellent soft-touch and sealing properties.

Typical Applications: Seals, gaskets, soft-touch grips, and automotive trim.

Common Additives Used to Improve Plastic Molding Material

Performance

Additives play a crucial role in enhancing the properties of plastics and reducing production costs. Below are some common types of additives and their functions:

Reinforcing Fillers

- Fibers (e.g., glass fiber) improve mechanical strength.

- Asbestos enhances heat resistance.

- Mica increases electrical insulation.

- Graphite and molybdenum disulfide improve wear and abrasion resistance.

These fillers can also help lower material costs by reducing the amount of base resin required.

Plasticizers:Improve flexibility and reduce brittleness by increasing the plasticity of the material.

Hardeners / Curing Agents:Facilitate cross-linking in thermosetting polymers, converting linear molecules into a three-dimensional structure for improved thermal and mechanical stability.

Colorants:Include pigments and dyes used to give plastics vibrant colors and finishes. Special effects like fluorescence or phosphorescence can also be achieved with specific colorants.

Stabilizers:Protect plastics from degradation due to heat, UV light, or oxidation during processing and use, thereby extending product lifespan and maintaining material performance.

Lubricants:Assist in processing by reducing friction during molding, aiding in de-molding, and improving surface smoothness.

Get Our More Material Options

Conclusion

Understanding the differences between plastic injection molding materials is key to achieving better performance, durability, and long-term value in your final product. If you need guidance in selecting the right injection molding material for your custom part, our experts can help you explore a full range of plastic molding solutions.