In rubber injection molding, demolding is far more than simply taking a part out of the mold, it is a decisive step that affects product quality, efficiency, and cost. Unlike plastics, rubber’s elasticity and adhesion make demolding particularly challenging, often leading to surface defects, deformation, or ejector marks if not handled properly.

What is Demolding?

Demolding is the final step in the rubber molding process, where the finished part is carefully removed from the mold after curing. Although it may appear straightforward, this stage has a direct impact on product quality and production efficiency. In modern manufacturing, automated demolding systems add consistency and reliability, making this step essential for producing high-quality rubber products.

Demolding Process: How It’s Done

Demolding a rubber part involves a series of careful steps to ensure quality and prevent damage:

- Wait for Proper Cooling

Ensure the part is fully cured and cooled. Premature ejection can cause deformation or warping.

- Check Mold and Part

Inspect the mold and the part for any sticking areas or residue. Apply release agent if necessary.

- Activate Ejection Mechanism

Use ejector pins, sleeves, or stripper plates to gradually push the part out. Avoid excessive force to prevent marks or tears.

- Support Delicate Areas

For thin or intricate sections, provide manual or mechanical support during ejection to maintain shape.

- Remove the Part Carefully

Gently lift or slide the part out of the mold, ensuring no contact with sharp edges or surfaces that could scratch it.

- Inspect for Defects

Check for surface blemishes, deformation, or ejector marks. Address any issues before the next production cycle.

Why Is It Difficult to Demold Rubber Products?

Adhesion to the Mold

Rubber’s natural stickiness can make parts cling tightly, especially if release agents are insufficient or improperly applied.

Mold Design and Condition

Small draft angles, complex shapes, or worn/rough surfaces increase difficulty.

Environmental Factors

Variations in temperature and humidity can affect rubber properties and the ease of demolding.

Material Properties

Compound type, fillers, and additives affect shrinkage and elasticity, influencing how easily parts release.

Process Parameters

Variations in curing time, temperature, injection pressure, or speed can increase adhesion, making demolding harder.

Release Agent Application

The choice, frequency, and method of release agent use are critical. Inconsistent or unsuitable application can worsen sticking.

Defects in Rubber Products Caused by Poor Demolding

Poor demolding can lead to several defects that compromise the quality and functionality of rubber products:

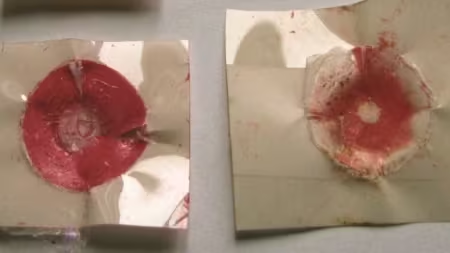

1. Tearing:

Rubber may tear during demolding due to excessive adhesion or insufficient draft angles.

2. Deformation:

Improper demolding can distort parts, causing them to fail dimensional or functional requirements.

3. Structural Rips:

Larger rips that penetrate deeper into the product can weaken its structural integrity.

4. Sticking to the Mold

Insufficient release agents or rough mold surfaces can cause the rubber to stick, leaving surface defects.

5. Delamination:

Poor adhesion between rubber layers or between rubber and other materials can lead to layer separation, compromising strength.

6.Ejector Marks:

Marks or indentations left by ejector pins or mechanical ejectors can appear on the surface if the part is not properly supported or the ejection force is too high.

How to Prevent Difficult Demolding of Rubber Products?

Optimize Mold Design

Use adequate draft angles (1°–3°) and smooth, simple mold shapes.

Use Release Agents

Incorporate internal release agents into the rubber compound or apply external agents evenly to reduce sticking.

Control Process Parameters

Optimize injection pressure, speed, curing time, and temperature to ensure proper vulcanization and prevent excessive adhesion.

Adjust Material Formulations

Modify rubber compounds with suitable vulcanizing agents, accelerators, fillers, and additives to reduce sticking and improve release.

Maintain and Treat Molds

Keep molds clean and apply surface treatments (plating, Teflon, or sandblasting) to maintain smooth surfaces and reduce adhesion.

Improve Demolding Techniques

Use automated systems (ejector pins, air ejection, robotics) and train workers in proper manual techniques for consistent, damage-free release.

Conclusion

Demolding is a key step that directly impacts the quality of rubber parts. With extensive experience in custom injection molding service, Zhongren ensures smooth demolding through optimized mold design, advanced surface treatments, and strict quality control. We deliver reliable, defect-free rubber components tailored to your needs.