Waterproof gaskets provide reliable sealing solutions that prevent water ingress, protect equipment or outdoor electrical connections, and ensure long-term performance in various systems. In this guide, we explore why waterproof gaskets are necessary, and why choosing a professional supplier is crucial.

Why Are Waterproof Gaskets Necessary?

Waterproof gaskets are designed to create a tight seal between two surfaces, preventing water, moisture, and other fluids from penetrating sensitive areas. Their role is critical in applications where exposure to water or other liquids can lead to equipment failure, corrosion, or electrical hazards. In addition to water protection, these gaskets also offer resistance against dust, contaminants, and temperature variations, ensuring devices and systems maintain operational integrity.

Common Applications of Waterproof Rubber Gaskets

Waterproof gaskets are used across various industries, each with specific requirements depending on the environmental conditions and operational demands. Some of the most common applications include:

- Plumbing and water systems: Gaskets provide reliable seals for faucets, pipe joints, valves, and water pumps.

- Home appliances: Washing machines, water heaters, and dishwashers utilize waterproof gaskets.

- Automotive components: Engines, radiators, and door seals depend on waterproof rubber gaskets.

- Industrial machinery: Equipment exposed to water, chemicals, or humidity requires gaskets.

- Outdoor electrical connections: weatherproof electrical gasket for electrical outlet, Electrical connections, etc.

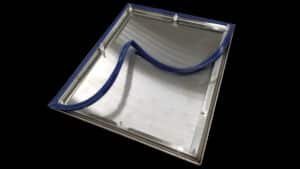

Custom Waterproof Gasket Solutions

Common Materials for Waterproof Gaskets

The performance of a rain block weatherproof gasket largely depends on the material used. Some commonly used materials include:

EPDM: EPDM provides resistance to water, UV, Ozone, weather properties, and durability.

NR: NR offers high elasticity and good mechanical properties at low cost. It is resistant to water but not oils.

Silicone Rubber: Silicone features high temperature resistance, excellent flexibility, and is food-safe. Silicone gaskets maintain their shape under varying environmental conditions, making them suitable for both indoor and outdoor applications.

FKM/Viton: FKM is highly resistant to chemicals, oils, and heat. This material is ideal for automotive and industrial applications where chemical exposure is a concern.

NBR: NBR resists oil, water and can perform in moderate temperatures. The NBR gasket commonly used in automotive and hydraulic systems.

Manufacturing Processes for Waterproof Rubber Gaskets

Producing high-quality waterproof gaskets requires precise manufacturing processes that ensure durability, dimensional accuracy, and consistent sealing performance. The general process for creating waterproof gaskets involves several steps:

- Material Preparation: The raw rubber or elastomer is mixed with additives to achieve the desired properties, such as flexibility, hardness, and water resistance.

- Mold Design and Fabrication: Molds are carefully designed with tight tolerances to achieve precise dimensions and uniform sealing surfaces. As even minor deviations can compromise the gasket’s ability to prevent water ingress.

- Forming Process: The prepared material is shaped using techniques such as compression molding, injection molding, or transfer molding. During this stage, the material is evenly distributed within the mold to form a consistent and reliable gasket profile.

- Curing/Vulcanization: The shaped gaskets undergo a curing or vulcanization process to enhance their elasticity, strength, and resistance to environmental factors.

- Post-Processing and Inspection: After molding, gaskets are trimmed, inspected, and tested for dimensional accuracy, hardness, and sealing effectiveness.

Choose Zhongren for Water-resistant Gasket Solutions

Zhongren offers reliable rubber gasket solutions backed by extensive experience, precise manufacturing, and strict quality control. No matter whetherproof outdoor electrical connections or weatherproof electrical outlet gaskets, Zhongren supplies tailored solutions to meet the specification requirements.