Nylon injection molding is a key manufacturing process for creating durable, precise parts used in industries like automotive, electronics, and medical. Known for its strength and versatility, nylon custom molded plastic requires careful control to achieve high-quality results.

What is Nylon?

Nylon, a polyamide thermoplastic, is produced through condensation polymerization of diamines and dicarboxylic acids or ring-opening polymerization of caprolactam. In nylon injection molding, it is valued for its mechanical strength, ranging from 50 to 100 MPa, and low friction coefficient of 0.1 to 0.3. Nylon resists chemicals like oils and solvents and withstands temperatures up to its melting point. However, its moisture absorption can affect dimensional stability, requiring pre-drying to below 0.2% moisture content. Nylon provides good electrical insulation, with a dielectric strength of 20-30 kV/mm.

Main Types of Nylon

- Several nylon types are used in nylon plastic injection molding, each suited to specific needs:

- PA6 (Nylon 6): Made from caprolactam, it has a melting point of 220°C and offers flexibility and impact resistance. Its higher moisture absorption suits parts like clips.

- PA66 (Nylon 66): Formed from hexamethylenediamine and adipic acid, it has a 265°C melting point and greater rigidity, ideal for structural components in nylon molding.

- PA11 and PA12: Bio-based, with lower moisture absorption (1-2%) and melting points of 180-190°C, used for flexible tubing in nylon injection.

- Glass-Filled Variants: Adding 10-40% glass fibers boosts strength by up to 30% and reduces shrinkage to 0.2-1%, suitable for high-load parts.

Advantages of Nylon Injection Molding

Nylon injection molding provides multiple benefits that enhance its suitability for various nylon manufacturing needs.

High Strength-to-Weight Ratio

Nylon parts offer significant strength while remaining lightweight, making them ideal for applications in automotive and aerospace industries where weight reduction is critical without compromising structural integrity.

Cost-Effectiveness

Affordable raw nylon materials and the ability to produce high volumes with minimal waste reduce per-part costs. Tooling costs in nylon plastic injection molding are offset by large production runs.

Design Flexibility

The nylon injection molding process supports complex geometries, including thin walls and intricate features, enabling the production of detailed designs that are challenging with other materials.

Recyclability

Certain nylon grades, such as PA11, align with sustainable manufacturing practices by supporting recyclability, reducing environmental impact in nylon molding processes.

Disadvantages of Nylon Injection Molding

Despite its strengths, nylon injection molding has limitations that manufacturers must address to ensure quality outcomes.

Shrinkage

Shrinkage rates of 1-2% during cooling can cause warping or dimensional inaccuracies, particularly in parts with uneven sections, requiring precise mold design in the nylon injection molding process.

Thermal Degradation

Processing temperatures exceeding 300°C can cause discoloration or material degradation, necessitating strict temperature control during nylon plastic injection molding to maintain part quality.

Processing Sensitivity

Nylon requires thorough drying and precise parameter control to avoid defects like bubbles or splay marks, adding complexity to the nylon molding process and increasing setup time.

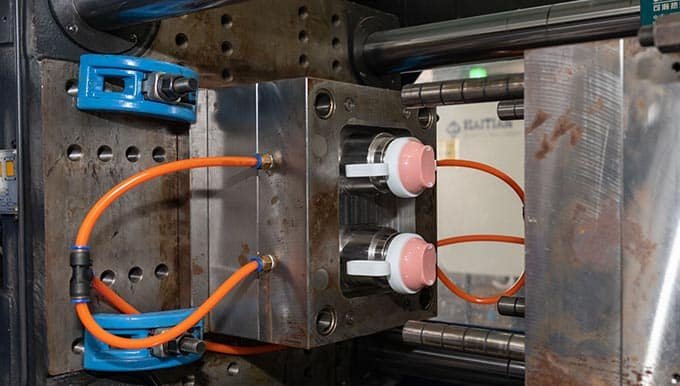

Nylon Injection Molding Process

The nylon injection molding process begins by feeding dried nylon pellets into the injection molding machine hopper. These pellets are then melted under controlled temperatures. The molten nylon is injected at high pressure into the mold cavity. The process comprises several stages:

- Material drying: Critical to eliminate moisture.

- Melting and injection: Molten nylon is injected rapidly into the mold.

- Holding or packing phase: Maintains pressure to compensate for material shrinkage and ensures proper filling.

- Cooling: Controlled cooling solidifies the part.

- Ejection: Once solidified and cooled, the part is ejected carefully to avoid deformation.

Mold Design Guidelines for Nylon Injection Molding

Effective mold design addresses nylon’s unique properties to ensure part consistency and moldability.

Wall Thickness

Uniform wall thickness between 0.76 and 2.92 mm is recommended for nylon molding to prevent uneven cooling and warping. Variations should not exceed 10-15% between adjacent walls, and thicknesses above 6 mm are discouraged due to extended cooling times. Nylon’s low melt viscosity allows thinner walls compared to other thermoplastics, supporting lightweight designs in the nylon injection molding process.

Draft Angles

Nylon’s low friction coefficient allows molding without draft angles for certain flat-surfaced components, such as gears. However, applying draft angles of 0.5-1° per side reduces cycle times and eases ejection in nylon plastic injection molding, particularly for textured or deep parts, improving production efficiency.

Radii

Corner radii of at least 0.5 mm are critical to minimize stress concentrations in nylon injection molding. For optimal performance, radii should be 75% of the nominal wall thickness to enhance material flow and reduce the risk of cracks or incomplete filling during the nylon molding process.

Gates

Large gates, such as submarine or hot runner systems, with diameters 0.5-1.5 times the wall thickness, ensure proper material flow and packing in nylon injection. Hot runner systems reduce shear stress and improve gate freeze control, minimizing defects like voids.

Venting

Vents with depths of 0.02-0.05 mm along parting lines are necessary to release trapped air, preventing burn marks or voids in the nylon injection molding process. Multiple vents enhance part quality, particularly for complex geometries.

Ribs and Bosses

Ribs should have a thickness of 50-60% of the nominal wall thickness, with heights not exceeding three times the thickness, to avoid sink marks. Bosses require fillets at the base to reduce stress, ensuring durability in nylon molding applications.

Cooling Channels

Cooling channels, placed 10-15 mm from cavity surfaces, maintain consistent mold temperatures in nylon plastic injection molding. Uniform cooling prevents warpage and supports efficient cycle times, with simulation tools aiding optimal placement.

Applications of Nylon Injection Molding

Due to its superior balance of mechanical and chemical properties, nylon molded parts find uses in:

- Automotive components: Gears, bushings, and under-the-hood parts.

- Electrical and electronic housings: Enclosures, insulators and connectors.

- Consumer goods: Sporting equipment, tool handles, furniture parts, and fasteners.

- Industrial machinery: Bearings, rollers, and connectors.

- Medical: Tubing and clamps.

Conclusion

Nylon injection molding delivers robust, precise components by leveraging nylon’s strength and flexibility. Proper material selection, mold design, and processing conditions ensure defect-free parts. Zhongren offeres nylon plastic injection molding and optimizes injection molding paramaters to achieve high quality molded nylon parts.