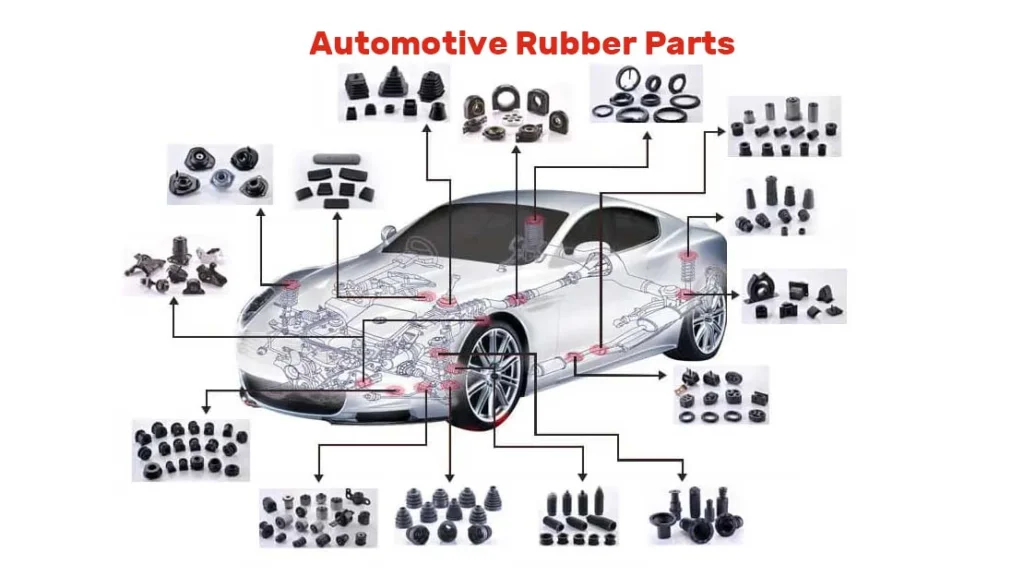

Automobile rubber parts play a vital role in the overall performance and safety of modern vehicles. From sealing and vibration damping to protecting components from wear and environmental damage, auto rubber parts are indispensable in automotive design and manufacturing. This article explores why rubber auto parts are vital for durable, reliable vehicles.

Common Rubber Car Parts

Rubber auto parts excel in heat resistance, durability, and pressure tolerance, ensuring reliable performance under demanding conditions.

Seals and Gaskets

Seals and gaskets prevent leaks and ensure tight connections between various automotive components, maintaining system integrity by sealing gaps and joints, containing fluids, and keeping contaminants out.

Examples:

- Engine gaskets

- Oil seals

Material Considerations

Materials are selected based on their ability to withstand the specific conditions they will encounter:

Nitrile Rubber (NBR): Known for its excellent oil and fuel resistance, NBR is commonly used in oil seals and gaskets that come into contact with petroleum-based fluids. Its temperature range (−40°C to 120°C) makes it suitable for engine and transmission applications.

Silicone Rubber: With excellent thermal stability and resistance to both low and high temperatures (−60°C to 200°C), silicone rubber is ideal for engine gaskets exposed to extreme heat. It also provides good resistance to weathering and ozone.

Fluoroelastomer (FKM/Viton): Offers superior chemical and heat resistance, making it suitable for gaskets and seals in high-temperature and aggressive chemical environments, such as fuel system seals.

Hoses and Tubes

Hoses and tubes transport fluids and gases within the vehicle, connecting components in systems like cooling, fuel, and braking, ensuring efficient fluid flow.

Examples:

- Coolant hoses

- Fuel lines

Material Considerations:

Different rubber materials are chosen to ensure durability and resistance to specific fluids and environmental conditions:

EPDM Rubber: Ideal for coolant hoses due to its excellent resistance to heat, ozone, and aging. It can handle temperatures from −40°C to 150°C, making it perfect for radiator and heater hoses.

Fluorocarbon Rubber (FKM): Known for its high resistance to fuels, oils, and chemicals, making it suitable for fuel lines. Its temperature range (−20°C to 250°C) ensures it performs well in high-temperature environments.

Nitrile Rubber (NBR): Used for oil and fuel hoses due to its good oil resistance. It is suitable for applications with temperatures ranging from −40°C to 120°C.

Belts

Belts transmit power between engine components, ensuring synchronized operation of systems like the camshaft and crankshaft.

Examples:

- Timing belts

- Serpentine belts

Material Considerations:

Durability and resistance to wear and environmental factors are critical for belt materials:

Neoprene Rubber: Commonly used in serpentine belts for its good abrasion resistance, flexibility, and moderate oil resistance. It can withstand temperatures from −40°C to 120°C.

HNBR (Hydrogenated Nitrile Butadiene Rubber): Used in timing belts for its high resistance to heat, oil, and chemical exposure. HNBR can handle temperatures from −40°C to 150°C, making it suitable for high-stress applications.

Bushings and Mounts

Bushings and mounts cushion between moving parts, reducing vibration and noise, enhancing vehicle comfort and stability, and absorbing shocks.

Examples:

- Suspension bushings

- Engine mounts

Material Considerations:

Materials are selected for their ability to withstand mechanical stress and environmental factors:

Polyurethane: Known for its high durability, resistance to wear, and low compression set. It is often used in suspension bushings where long-lasting performance and reduced deflection are required.

Natural Rubber: Provides excellent vibration damping properties and flexibility, making it suitable for engine mounts to reduce engine vibrations transmitted to the vehicle body. It can operate in temperatures ranging from −40°C to 80°C.

Weatherstripping

Weatherstripping seals gaps around windows and doors, preventing water, dust, and air from entering, maintaining a comfortable interior environment, and enhancing vehicle aerodynamics.

Examples:

- Door seals

- Window seals

Material Considerations:

Resistance to environmental factors is crucial for weatherstripping materials:

EPDM Rubber: Offers excellent resistance to UV radiation, weathering, ozone, and temperature variations, making it ideal for exterior seals exposed to the elements. It can operate in temperatures from −40°C to 150°C.

Thermoplastic Elastomers (TPE): Sometimes used for their flexibility, ease of manufacturing, and good weather resistance.

Tires

Tires provide traction, stability, and comfort, supporting vehicle load and ensuring safe driving in various conditions.

Material Considerations:

Tire materials must balance strength, durability, and flexibility:

Natural Rubber and Synthetic Rubber Blends: Used to achieve a combination of strength, wear resistance, and flexibility. Synthetic rubbers like SBR (styrene-butadiene rubber) and BR (butadiene rubber) enhance tire performance. These materials provide the necessary traction and durability across a wide temperature range (−40°C to 70°C).

Bellows and Boots

Bellows and boots protect moving parts from dust, dirt, and moisture while allowing flexibility and movement, commonly used in steering and suspension systems.

Examples:

- CV joint boots

- Steering rack bellows

Material Considerations:

Materials must resist abrasion and environmental exposure:

Neoprene Rubber: Known for its durability, flexibility, and resistance to weathering and oils. Suitable for temperatures ranging from −40°C to 120°C.

Nitrile Rubber (NBR): Good abrasion resistance and oil resistance, making it suitable for applications exposed to oil and grease. It can operate in temperatures from −40°C to 120°C.

Grommets and Plugs

Grommets and plugs protect wires and cables passing through metal panels, preventing abrasion and securing openings against contaminants.

Examples:

- Wiring grommets

- Panel plugs

Material Considerations:

Materials are chosen for their durability and environmental resistance:

EPDM Rubber: Offers excellent resistance to weathering, ozone, and aging, suitable for outdoor applications. It can handle temperatures from −40°C to 150°C.

Silicone Rubber: Used for its flexibility and high-temperature resistance, making it suitable for environments with temperatures ranging from −60°C to 200°C.

Bumpers and Covers

Bumpers and covers protect vehicle components from impacts and abrasions, absorbing shocks and preventing damage to underlying parts.

Examples:

- Bumper covers

- Protective covers for components

Material Considerations:

Materials must provide high-impact resistance and flexibility:

Thermoplastic Elastomers (TPE): Combine rubber-like flexibility with the ability to be molded into complex shapes, used in protective covers. They offer good impact resistance and can operate in temperatures from −40°C to 120°C.

Polyurethane: Known for its impact resistance and durability, often used in bumper covers. It can handle a wide temperature range (−40°C to 80°C) and provides good abrasion resistance.

Manufacturing Process for Automotive Rubber Parts

The common manufacturing processes for automotive rubber components include injection molding, compression molding, transfer molding, calendaring, and extrusion. Each of these processes is chosen based on the specific requirements of the component, such as volume, complexity, and material properties.

Injection Molding

Injection molding service is widely used for high-volume production of complex rubber parts with precise dimensions. This process involves heating rubber and injecting it into a mold under high pressure, where it cures into the final shape. It is particularly suitable for components like seals, gaskets, and bushings due to its ability to produce intricate shapes with high consistency and minimal waste.

Compression Molding

Compression molding process is used for medium-hard compounds and low-volume production. It involves placing a preformed rubber blank into a heated mold cavity, where it is compressed and cured. This method is ideal for producing parts like bushings, mounts, and some types of seals and gaskets, especially when the raw materials are expensive or the required volumes are low.

Transfer Molding

Transfer molding is similar to compression molding but involves pre-heating the rubber, which reduces curing time and improves flow. This process is used for more complex shapes and is suitable for components like bushings and mounts that require a strong mechanical bond.

Extrusion

Rubber extrusion is used to produce long, continuous shapes such as hoses, tubing, and weather stripping. The process involves forcing a rubber compound through a die to create the desired profile, which is then vulcanized to harden it. This method is ideal for producing parts that need to be flexible and durable, such as hoses and weather stripping.

Calendaring

Calendaring is used to produce rubber sheets and films by forcing softened rubber through counter-rotating rollers. This process allows for precise control over the thickness of the rubber but has higher operating costs. It is typically used for producing thinner and wider rubber parts like belts, tires, etc.

Zhongren: Your Trusted Partner for Custom Automobile Rubber Parts Solutions

As a professional manufacturer, Zhongren offers comprehensive one-stop services from mold design and fabrication to mass production. With advanced technologies and extensive industry experience, we are capable of producing a wide range of automobile rubber products to meet diverse specifications and high-performance requirements.

FAQ for Automotive Rubber Products

Does Zhongren accept small orders or prototype runs?

Absolutely. We support both small batch and large volume orders, offering flexible production solutions to match your project timeline and scale.

How does Zhongren assist clients with technical or design challenges?

Our experienced engineering team collaborates closely with clients, providing expert guidance on material selection, design optimization, and manufacturability to ensure the best final product.

What advantages does Zhongren offer compared to other manufacturers?

Zhongren’s integrated mold-making and production capabilities, combined with customized material modification expertise, allow us to deliver high-quality, tailor-made rubber parts with superior performance and reliable delivery.