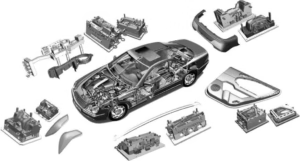

The automotive industry has long relied on innovative manufacturing techniques to produce high-quality, durable, and lightweight parts. Among these, automotive plastic injection molding stands out as a pivotal technology that enables the mass production of complex and precise components essential for modern vehicles. This article explores the fundamentals of injection molding automotive parts, highlighting its advantages, materials, production processes, and market trends.

What is Automotive Injection Molding?

Automotive plastic injection moulding is a precision manufacturing process where molten thermoplastic is injected under high pressure into a mold cavity, cooling and solidifying to form intricate automotive components. The process relies on three core components: an injection unit that melts and delivers the material, a mold (often called an automotive mold) that shapes the part, and a clamping unit that ensures precision. This method’s significance lies in its scalability. A single automotive plastic mold can produce thousands of identical parts, ensuring consistency for high-volume manufacturing.

Advantages of Injection Molding in Automotive Applications

Injection molding automotive parts offers numerous advantages that make it the preferred method for producing plastic components in vehicles:

Lightweighting: Automotive parts molding replaces heavier metal components with plastics, reducing vehicle weight by 30-50%. This improves fuel efficiency in internal combustion vehicles and extends range in electric vehicles (EVs).

Cost-Effectiveness: Injection molding automotive processes boast rapid cycle times—often under 60 seconds. And high-volume production with injection molding automotive processes reduces per-unit costs, making it economical for mass manufacturing.

Design Flexibility: The precision of automotive molds enables complex geometriesand intricate designs unachievable with traditional methods.

High Precision and Consistency: Automotive molds ensure tight tolerances(as low as ±0.01 mm) and repeatability, essential for parts that must fit precisely within assemblies.

Material Versatility: A wide range of plastics can be used, each offering specific mechanical, thermal, and chemical properties tailored to automotive requirements.

Reduced Waste: The process is efficient, with excess material often recyclable, supporting sustainable manufacturing practices.

Surface Quality: Automotive plastic moulds produce parts with smooth, aesthetically pleasing finishes, ideal for visible components like dashboards or exterior panels.

Production Applications of Automotive Injection Molding

Automotive plastic injection molding is employed to produce a vast array of vehicle parts. Some of the most common components manufactured using this technology include:

Components Under-the-Hood

Automotive injection molding is widely used to produce functional and safety-critical components under the hood, such as engine covers, battery casings, fluid reservoirs, and sensor housings.

Exterior Components

For the vehicle’s exterior, injection molding enables the efficient production of complex and lightweight parts like bumpers, grilles, mirror housings, and trim pieces.

Interior Components

Inside the cabin, this molding process is ideal for crafting dashboards, door panels, center consoles, and air vents.

Materials Used in Automotive Injection Molding

From lightweight interiors to robust functional components, material selection in automotive injection molding need to ensures durability, aesthetics and functionality.

- Polypropylene (PP): Lightweight and chemically resistant, PP excels in automotive plastic moulds for interior parts like dashboards and under-hood components.

- Acrylonitrile Butadiene Styrene (ABS): Known for toughness and glossy finishes, ABS is ideal for exterior panels and interior trim in molding automotive processes.

- Polycarbonate (PC): With optical clarity and high impact resistance, PC is perfect for headlamp lenses and transparent covers in automotive molds, enduring temperatures up to 140°C.

- Nylon (Polyamide, PA): High-strength PA, often glass-filled (PA-GF), supports gears and bearings in automobile injection molding, offering superior wear resistance.

- Polyethylene (PE): Flexible and impact-resistant, PE is used for fluid reservoirs and casings in automotive parts mold production, with HDPE providing added strength.

- Polyoxymethylene (POM): POM’s low friction and dimensional stability make it ideal for precision parts like fuel system components in injection molding automotive applications.

- Polymethyl Methacrylate (PMMA): Known as acrylic, PMMA’s transparency and scratch resistance suit light covers and decorative trim in automotive molds.

- Polyvinyl Chloride (PVC): Durable and cost-effective, PVC is used in automotive plastic moulds for interior trim, cable insulation, and flexible tubing.

- Polyurethane (PU): Thermoplastic PU (TPU) provides flexibility for seals and soft-touch grips, while thermoset PU is used for coatings and foams in automotive parts molding.

- Thermoplastic Elastomers (TPE): TPEs combine rubber-like flexibility with recyclability, ideal for weather seals and vibration-damping parts in molding automotive solutions.

- Polystyrene (PS): General-purpose or high-impact PS is used for lightweight interior components in automotive injection molding, offering cost-effective aesthetics.

- PC/ABS Blends: Combining PC’s impact resistance with ABS’s processability, PC/ABS is used for high-strength interior and exterior parts in automotive plastic injection moulding.

- Reinforced Composites: Glass- or carbon-fiber-reinforced plastics (e.g., PP-GF, PA-GF) enhance strength for structural components like EV battery trays in automotive molds.

- Thermosets (e.g., Epoxy, Phenolic): Heat-resistant thermosets support high-temperature parts like alternator housings in automobile injection molding.

Production Methods and Process of Automotive Injection Molding

The automotive injection molding process combines precision engineering with versatile methods to produce high-quality components, from intricate dashboards to robust battery casings. Key methods include:

Thermoplastic Injection Molding: The cornerstone of automotive parts molding, this method uses thermoplastics like polypropylene (PP) and ABS to create cost-effective, versatile parts with rapid cycle times, ideal for dashboards and exterior panels.

Gas-Assisted Injection Molding (GAIM): By injecting gas to form hollow sections, GAIM reduces material use and weight in large components like door panels, enhancing automotive plastic moulds efficiency.

Overmolding: This technique molds a secondary polymer over a substrate, enabling multi-material parts like soft-touch grips on rigid handles, optimizing ergonomics in automobile injection molding.

Insert Molding: Combining polymers with inserts (e.g., metal), insert molding enhances part strength for components like connectors, minimizing bulk in automotive parts mold production.

Elastomeric Injection Molding: Using materials like silicone or rubber, this method produces vibration-damping parts such as seals, offering flexibility and shock absorption in automotive injection molding.

Compression Molding: Raw plastic is heated and compressed in automotive molds, ensuring resilience for parts like interior trim, with cooling to maintain shape.

Thermosetting Injection Molding: Employing heat-resistant polymers like epoxy, this method creates durable parts for high-temperature applications, such as alternator housings, in automotive plastic injection moulding.

Considerations in Automotive Injection Molding

Successful automotive plastic injection moulding requires careful attention to several factors to ensure quality and efficiency:

Part Design: Uniform wall thickness (1.2-3 mm) prevents defects like sink marks. Draft angles (1-2°) and rounded corners ease ejection and reduce stress.

Mold Design: High-quality automotive molds, typically made from H13 steel or aluminum, incorporate optimized parting lines and cooling channels to enhance cycle times. Mold flow analysis predicts potential issues like warpage.

Process Parameters Setting: Injection pressure, temperature, cooling time, and injection speed must be carefully controlled.

Material Selection: Choosing the right thermoplastic balances cost, performance, and application needs, such as UV resistance for exterior parts.

Cost Management: Balancing quality, material costs, and cycle times is critical to achieving competitive pricing.

Auotmotive Injection Molding Market Trends

Demand for lightweight automotive parts molding solutions surges with electric vehicles (EVs). Smart manufacturing, integrating IoT and 3D-printed automotive molds optimizes production efficiency. These trends underscore the transformative potential of automotive plastic injection moulding in shaping next-generation vehicles.

Zhongren offers comprehensive, one-stop solutions for interior, exterior, and functional components. Our state-of-the-art automotive plastic moulds and rigorous quality control ensure precision and durability, tailored to your unique needs.

FAQ of Auotmotive Injection Molding

What is the best molding process for automotive injection molding parts?

Standard injection molding is the best process for most automotive parts due to its precision, speed, and cost-effectiveness.

What is the best material for injection molding automotive parts?

Common materials are polypropylene (PP), ABS, nylon (PA), and polycarbonate (PC), chosen based on part requirements like strength and heat resistance.