Custom Molding Factory for Material Handling Product

Custom Material Handling Parts Solution

Zhongren manufacture durable rubber, plastic, and polyurethane parts for conveyors, sorting equipment, and automated systems. all material handling components are custom-made to match your load, friction, and wear requirements, ensuring long service life.

- Design Optimization: Our engineers work closely with customers to refine designs, meet requirements, and enhance manufacturability.

- In-House Tooling: With in-house tooling, we shorten development time and ensure full control over quality and consistency.

- Material Expertise: Our experts help choose the right materials or modified compounds for specific automotive needs.

- Integrated Production: Molding, finishing, and assembly are managed in-house to simplify your supply chain and improve efficiency.

- Quality Assurance: Each project follows strict inspection and testing to ensure dimensional accuracy and reliable performance.

Your Best Partner for Custom Material Handling Parts Manufacturing

Zhongren serves buyers across the US, Europe, the Middle East, and Southeast Asia, mainly equipment manufacturers, distributors in logistics, mining, food processing, and automation.

We provide custom-molded rubber, plastic, and PU parts tailored to their environmental demands, supporting both prototyping and long-term production.Our Custom Material Handling Parts Showcase

Below are examples of the material handling components we’ve produced. We offer full customization and can manufacture according to your drawings or samples.

Our Handling Parts Manufacturing Capabilities

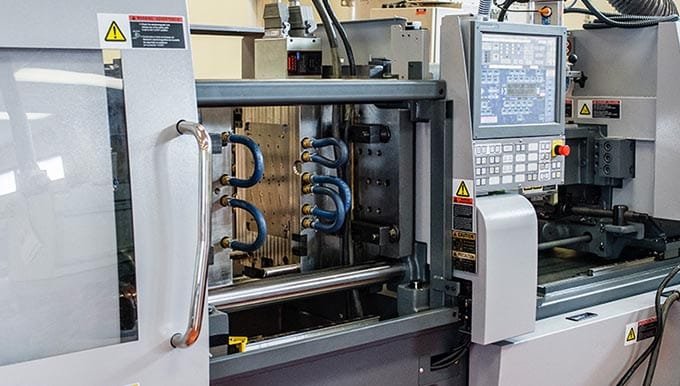

Our Machines for Custom Handling Parts

Have Any Questions for Automotive Parts Manufacturing?

What information do I need to provide to get an accurate quote for material handling parts?

We typically need drawings, material requirements, load conditions, working environment, quantity, and tolerance expectations to offer an accurate cost and lead time.

Can you help choose the right material if I’m unsure which one fits my application?

Yes. Share your load, speed, temperature, and operating conditions, and our engineering team will recommend suitable materials such as PU, nylon, HDPE, rubber, or composite structures.

What is the minimum order quantity (MOQ) for custom material handling components?

We support small batches for prototypes and ramp-up production, typically starting from 1–100 pcs depending on tooling requirements.

Can you replace or replicate an existing part if I only have a sample?

Yes. We can reverse-engineer samples, measure critical dimensions, match materials, and produce molds or machining tools for mass production.

Do you offer solutions for reducing noise, vibration, or friction in material handling systems?

We can adjust material hardness, add wear layers, or use low-friction plastics or rubber formulations to improve system stability and reduce noise.