Related Product

OEM Plastic Light Housing

Car headlight housings are essential components that provide heat dissipation, waterproofing, dust protection, and shock resistance, while seamlessly integrating with the lens, reflector, LED, and sealing elements to ensure reliable optical performance and safety.

| Feature | Description |

|---|---|

| Product Category | Automotive exterior parts |

| Mold | Customized |

| Custom Service | From Tooling to production |

| Product Material | Rubbers, plastics, or custom compound |

| Product Color | Custom color based on Pantone or RAL standard. |

| Molding Method | Injection Molding, compression Molding, extrusion |

| Secondary Finishing | Screen printing, laser engraving, spray painting, electroplating, etc. |

| Assembly Services | Insert molding, mechanical fastening, adhesive bonding, and welding |

| Packaging | Accept custom packaging |

Customized Headlamp Housing – From Mold Design to Production

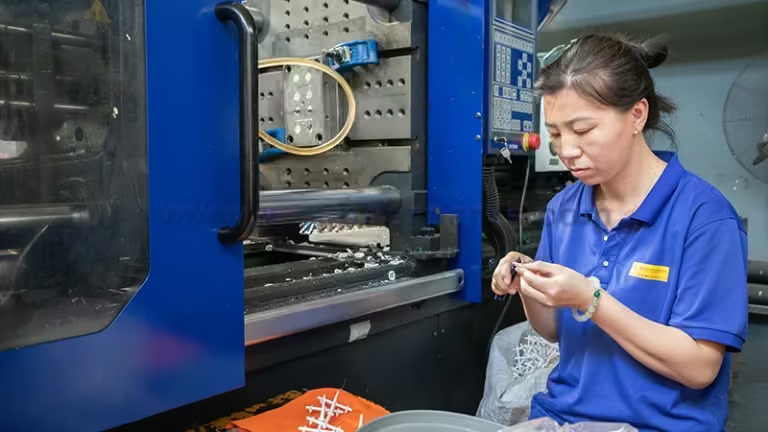

Zhongren specializes in full-process custom manufacturing of high-quality plastic headlamp housings with injection molding, covering mold design, material selection, injection molding, surface treatment, and precise assembly. We provide complete custom solutions for housings and matching EPDM/TPE rubber seals.

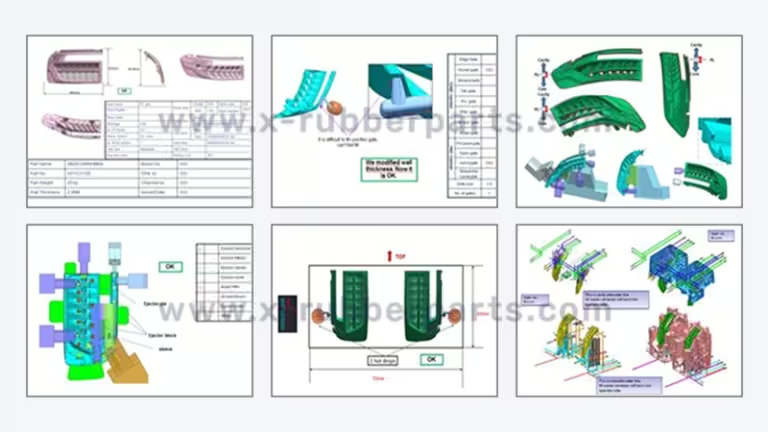

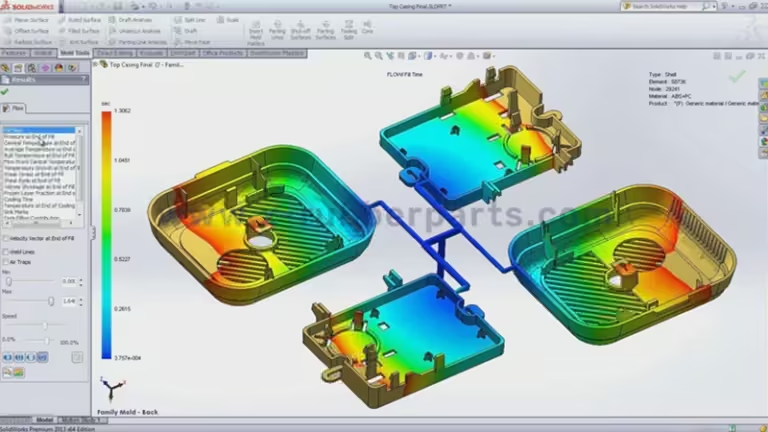

- During mold design, we optimize mold design with carefully planned runner layouts, cooling channels, and venting to ensure accurate dimensions and smooth surfaces.

- Common materials include PP, ABS, PC/ABS, and PA+GF, and we select materials based on client preferences when specified.

- Throughout injection molding, we strictly control process parameters to effectively prevent common defects like warpage, shrinkage, silver streaks, and air bubbles.

- During surface treatment, we apply professional finishing techniques such as painting and texturing to achieve the ideal balance of functionality and aesthetic appeal.

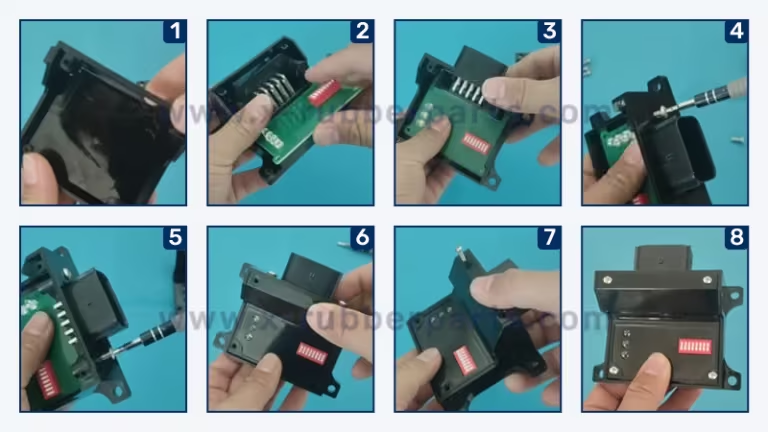

- During assembly, housings and rubber seals fit seamlessly with lenses and reflectors, meeting strict vehicle assembly standards.