Related Product

Custom Rubber Bumper

| Feature | Description |

|---|---|

| Product Category | Automotive exterior parts |

| Mold | Customized |

| Custom Service | From Tooling to production |

| Product Material | Rubbers, plastics, or custom compound |

| Product Color | Custom color based on Pantone or RAL standard. |

| Molding Method | Injection Molding, compression Molding, extrusion |

| Secondary Finishing | Screen printing, laser engraving, spray painting, electroplating, etc. |

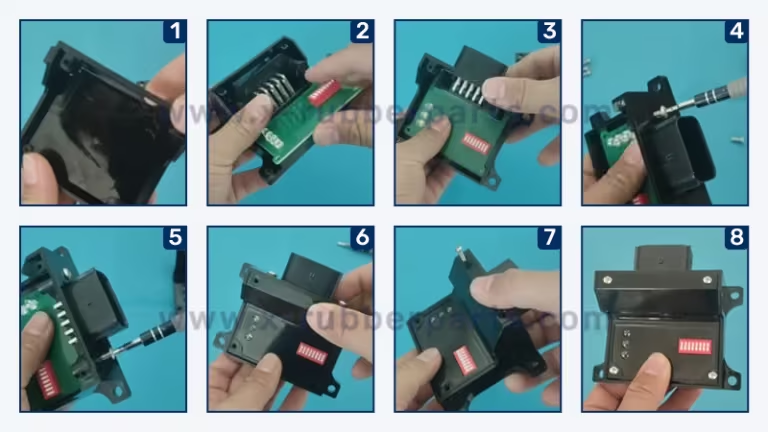

| Assembly Services | Insert molding, mechanical fastening, adhesive bonding, and welding |

| Packaging | Accept custom packaging |

Custom Car & Truck Rubber Bumper – From Mold Design to Production

Zhongren specializes in full-process custom manufacturing of rubber bumpers for cars and trucks. Commonly used materials include EPDM, NBR, silicone, and PU, selected according to client preferences when specified.

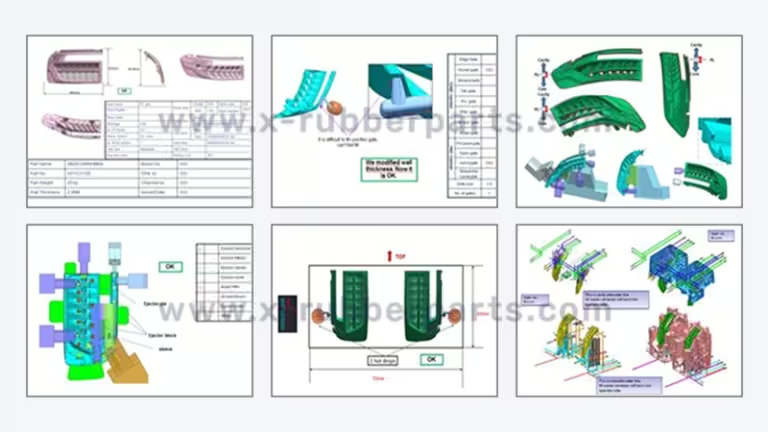

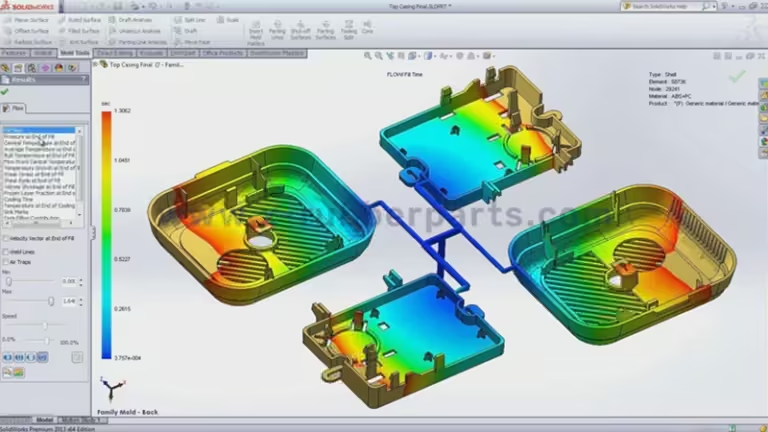

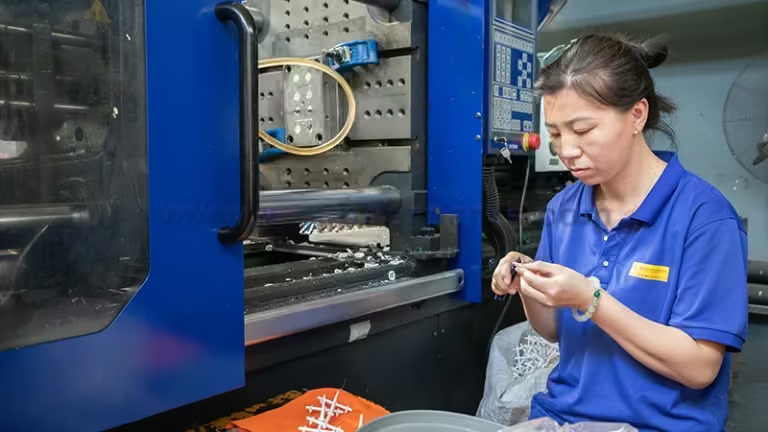

With an experienced engineering team, Zhongren can provide professional optimization suggestions based on your drawings to help reduce assembly difficulty. Our production process includes injection, compression, and extrusion, enabling precise fabrication of custom rubber bumpers in various shapes, sizes, and hardness levels. We also offer tailored surface finishes and assembly options to meet specific functional and aesthetic requirements.

Rubber Bumpers in Different Locations of the Car

Rubber bumpers are widely used in various areas of a vehicle, each with a specific protective and functional role:

- Engine Compartment: Engine mount and radiator bumpers reduce vibration, stabilize components, and extend service life. When customizing, material heat resistance and oil resistance (e.g., EPDM or NBR) should be carefully considered.

- Doors, Hood, and Trunk: Door stops, hood bumpers, and trunk bumpers prevent metal-to-metal contact, reduce closing noise, and enhance sealing. Custom design should focus on precise dimensions and compression set performance for reliable fit.

- Suspension and Chassis: Shock absorber bump stops and subframe bumpers absorb impact and prevent structural damage. These bumpers require high durability and resilience to withstand continuous heavy loads.

- Interior Components: Glove box, console storage, and headlight mounting bumpers provide cushioning, minimize noise, and protect delicate plastic parts. Customization should emphasize softness, precision molding, and long-term aging resistance.