Related Product

Custom Car Plastic Grille Molding Manufacturer

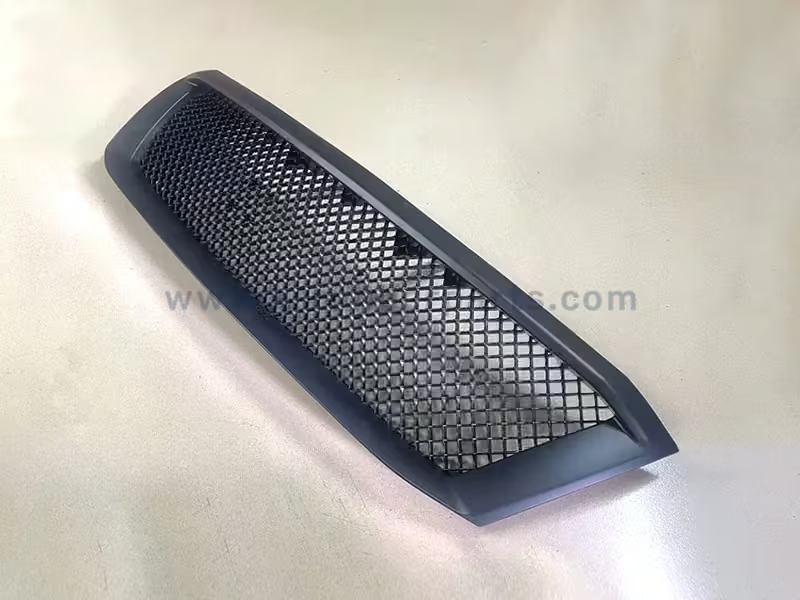

Car grilles serve as essential front-end assemblies, providing ventilation and structural support. They typically consist of the outer frame, slats, support brackets, trims, and rubber or plastic seals.

| Feature | Description |

|---|---|

| Product Category | Automotive exterior parts |

| Mold | Customized |

| Custom Service | From Tooling to production |

| Product Material | Rubbers, plastics, or custom compound |

| Product Color | Custom color based on Pantone or RAL standard. |

| Molding Method | Injection Molding, compression Molding, extrusion |

| Secondary Finishing | Screen printing, laser engraving, spray painting, electroplating, etc. |

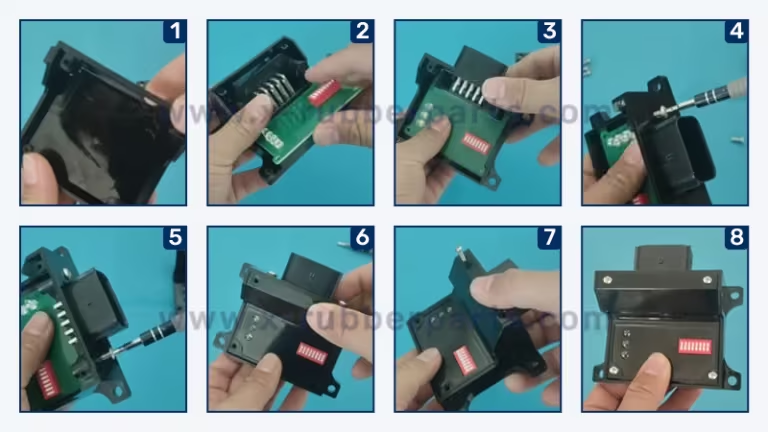

| Assembly Services | Insert molding, mechanical fastening, adhesive bonding, and welding |

| Packaging | Accept custom packaging |

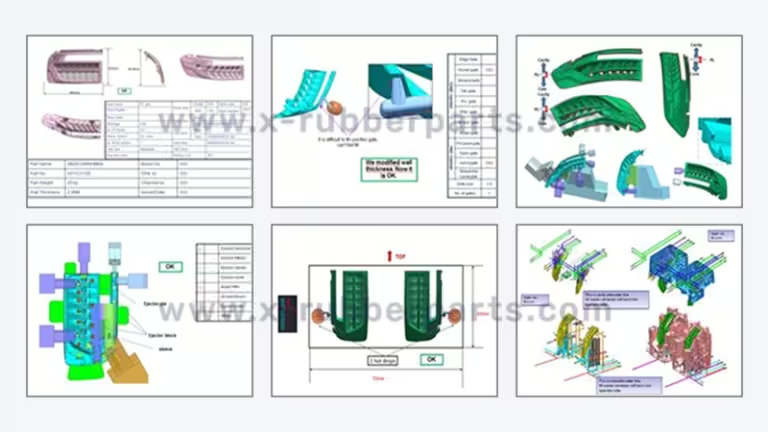

Custom Car Grille – From Mold Design to Production

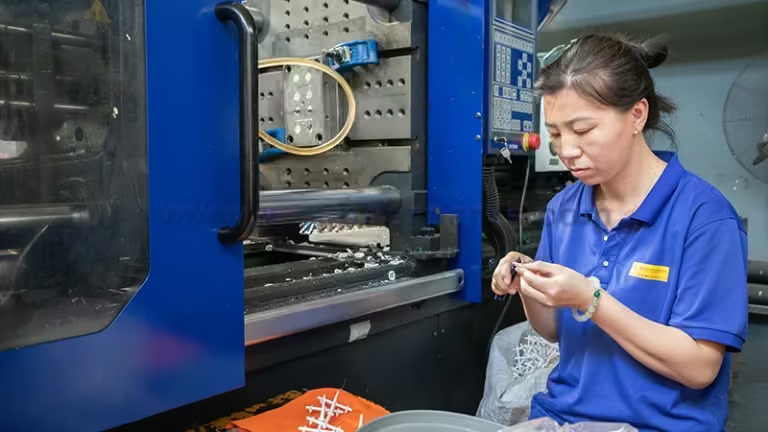

Zhongren specializes in custom car grilles, providing complete solutions from mold design to production. Common materials are ABS, PP, PC/ABS, and TPE/TPR. We can customize integrated car grilles or individual parts of car grilles, such as frames, slats, support brackets, and seals.

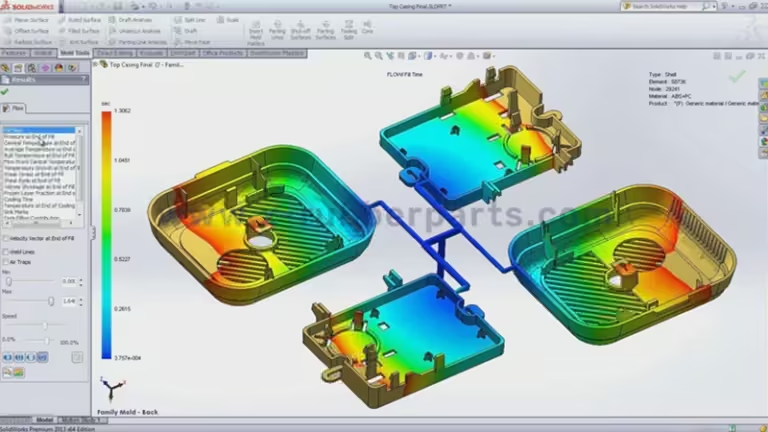

Our manufacturing process leverages detailed mold flow analysis to optimize material distribution, minimize potential defects such as sink marks or weld lines, and ensure uniform wall thickness across the grille structure. We focus on dimensional and structural accuracy to ensure installation compatibility with bumpers, headlights, and other front-end components.