Related Product

Custom Car Center Console Box & Bin

| Feature | Description |

|---|---|

| Product Category | Automotive internal parts |

| Mold | Customized |

| Custom Service | From Tooling to production |

| Product Material | Rubbers, plastics, or custom compound |

| Product Color | Custom color based on Pantone or RAL standard. |

| Molding Method | Injection Molding, compression Molding, extrusion |

| Secondary Finishing | Screen printing, laser engraving, spray painting, electroplating, etc. |

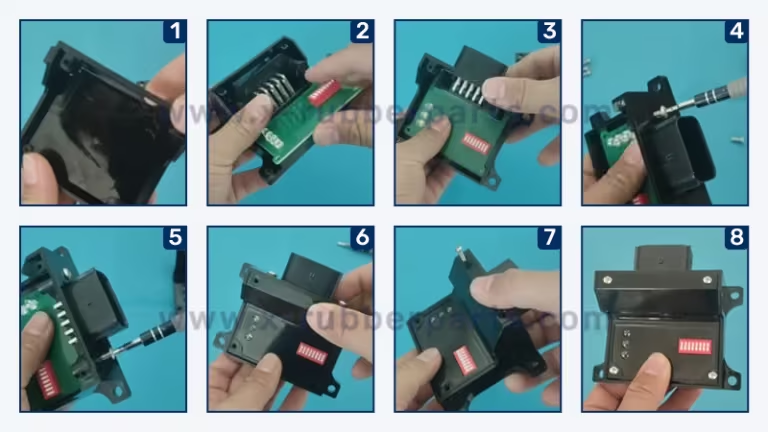

| Assembly Services | Insert molding, mechanical fastening, adhesive bonding, and welding |

| Packaging | Accept custom packaging |

Custom Car Center Console Storage Box – From Mold Design to Production

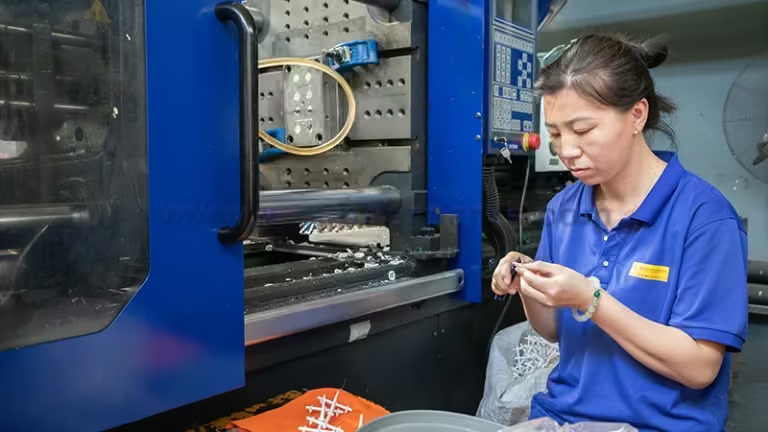

Zhongren specializes in custom car center console storage boxes, delivering complete solutions from mold design to final production. Commonly used materials include ABS, PP, PC/ABS, or TPE, with materials recommended according to specific customer requirements. We can produce the plastic main shell, cover, inner sections, and rubber gasket of the center console storage bins.

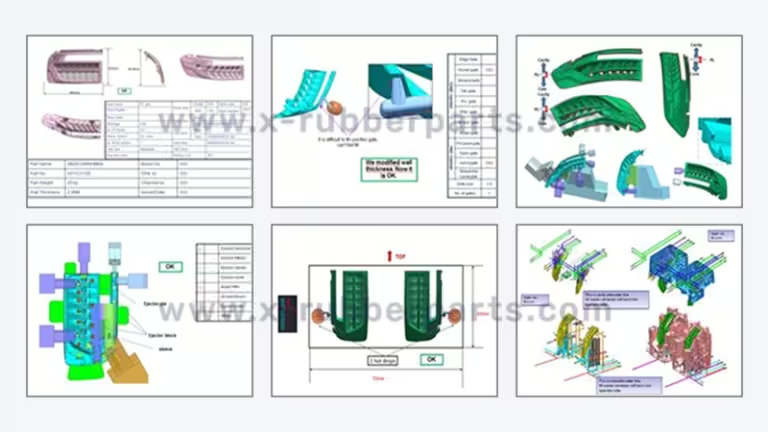

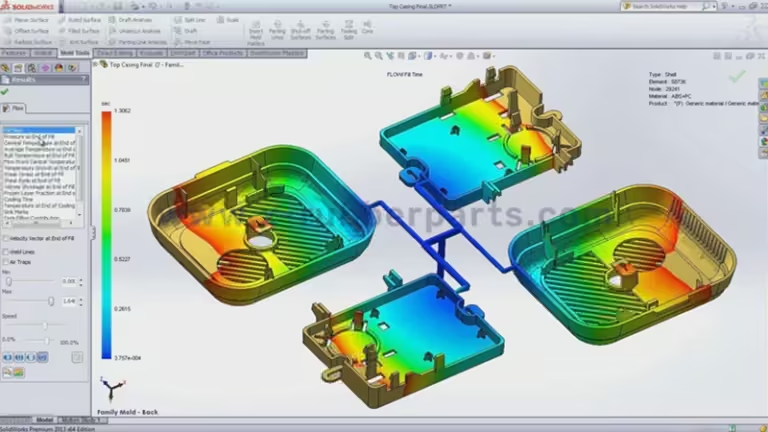

At Zhongren, our approach to customizing center console storage boxes begins with MFA and DFM evaluations. By simulating plastic flow, cooling, and potential weld line locations, we can proactively adjust wall thickness, gate positions, and reinforcement ribs, ensuring uniform filling, minimal shrinkage, and structural integrity.

Our engineers review DFM feedback to refine part geometry and assembly features, enhancing compatibility with adjacent interior components and reducing post-production adjustments. This iterative process ensures each storage box meets stringent dimensional and functional requirements while maintaining an aesthetic surface finish consistent with the vehicle’s interior.

Zhongren’s customization supports:

- Prototyping and pre-production validation: Simulated mold flow reduces trial-and-error in early stages.

- Complex mold optimization: Multi-cavity designs are evaluated for uniform quality and cycle efficiency.

- Precision assembly alignment: DFM-informed features improve ease of assembly and consistent fit.