Custom Molding Factory for Automotive Industry

Custom Automotive Parts Solution

Automotive components represent one of the largest segments of our business over the years. With rich experience in producing a wide range of parts from interior parts to structural components, we understand what it takes to meet tough automotive standards.

- Design Optimization: Our engineers work closely with customers to refine designs, meet requirements, and enhance manufacturability.

- In-House Tooling: With in-house tooling, we shorten development time and ensure full control over quality and consistency.

- Material Expertise: Our experts help choose the right materials or modified compounds for specific automotive needs.

- Integrated Production: Molding, finishing, and assembly are managed in-house to simplify your supply chain and improve efficiency.

- Quality Assurance: Each project follows strict inspection and testing to ensure dimensional accuracy and reliable performance.

Your Best Partner for Custom Plastic & Rubber Auto Parts Manufacturing

Zhongren provides high-quality custom automotive parts to clients in countries including the United States, Germany, Japan, and the United Kingdom, serving Tier 1 and Tier 2 auto suppliers, leading automotive manufacturers, OEM component producers, and aftermarket parts manufacturers.

Our Custom Automotive Parts Showcase

Below are examples of the automotive components we’ve produced. We offer full customization and can manufacture according to your drawings or samples.

Our Auto Parts Manufacturing Capabilities

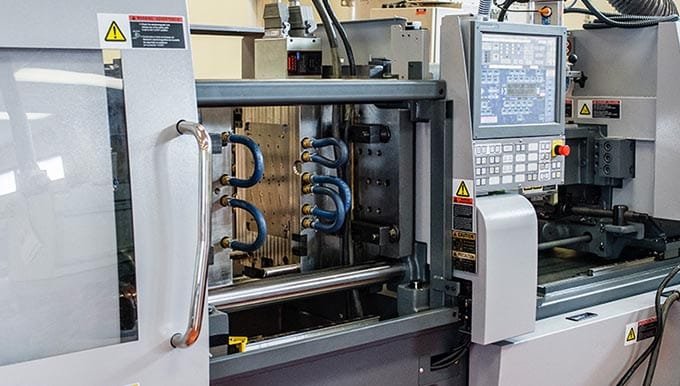

Our Machines for Automotive Custom Parts

Have Any Questions for Automotive Parts Manufacturing?

What types of automotive parts can you customize?

We can produce a wide range of plastic and rubber automotive components, including seals, bushings, grommets, covers, handles, and other precision-molded parts.

Can you help choose the right material for my automotive component?

Yes. Our engineers will recommend suitable materials based on your part’s working environment, temperature, and durability needs, such as ABS, PA, POM, PC, and PP for plastics, or EPDM, NBR, and silicone for rubber parts.

What’s the typical process for customizing automotive parts?

The process includes design evaluation → mold design → mold making → sample verification → mass production.

Do you provide mold design and manufacturing in-house?

Yes. We design and manufacture molds internally, allowing faster lead times, better precision, and lower total cost.

Do you offer design optimization or DFM feedback?

Yes, we provide free DFM analysis to improve manufacturability, reduce tooling cost, and enhance performance.

How can I get a quote for my custom automotive part?

Simply send us your drawings or requirements, and our engineering team will reply with a quotation and lead time within 24 hours.

Custom Molding Parts for Other Industrials

What Other Customer Say About Us

The parts always meet our strict quality standards, and their careful material choice and process control make us confident in every batch.

Michael ChenSenior Purchasing Manager

Working with the team is a breeze. Fast DFM feedback and quick production start help keep our projects on schedule.

Laura SmithSupply Chain Manage

The collaboration experience has been exceptional. The team is responsive, easy to communicate with, and adapts quickly to design changes, making the entire process smooth and hassle-free.

Javier RodriguezProcurement Director